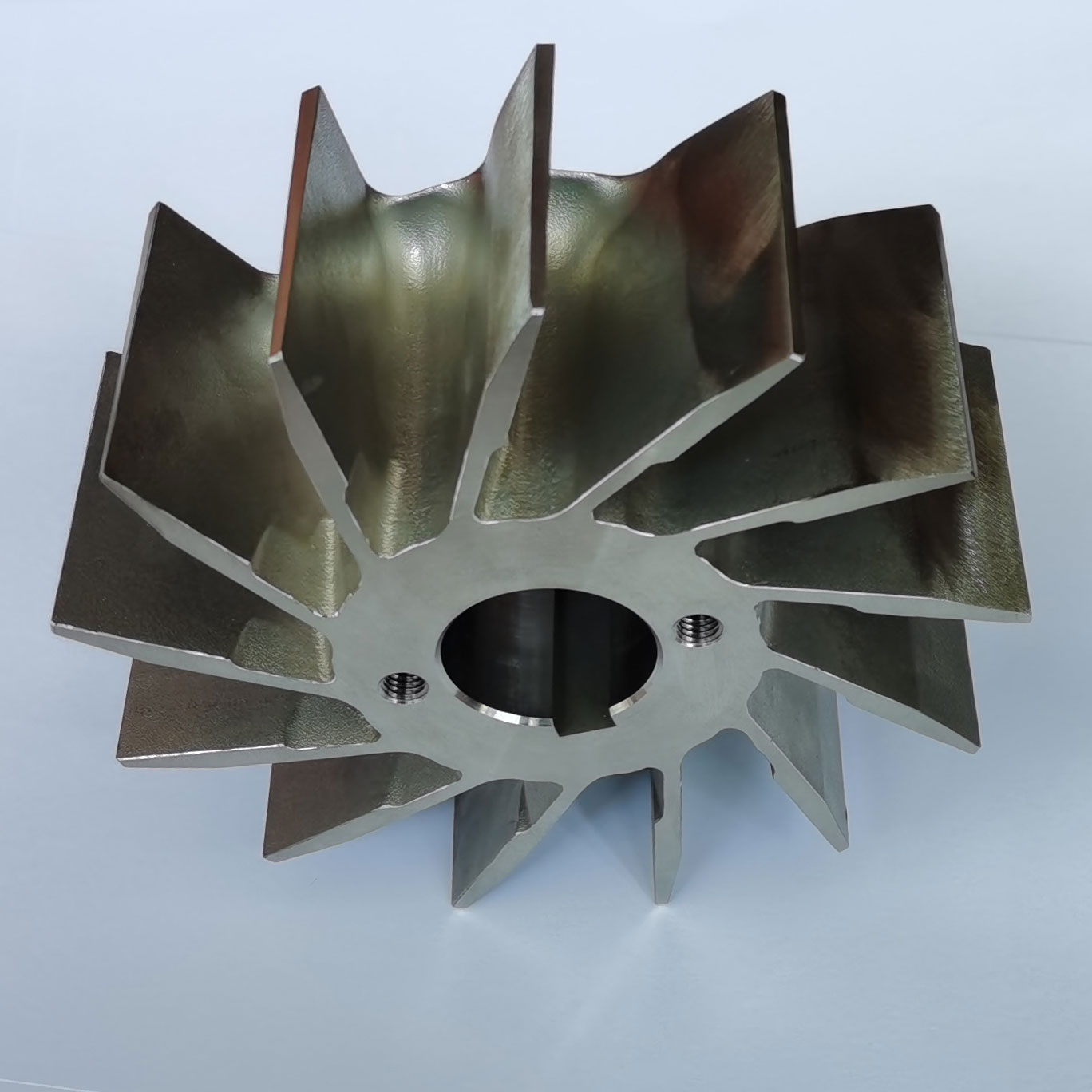

CF8M nkedo igwe anaghị agba nchara mepere emepe maka mgbapụta centrifugal site na ntinye ntinye ego,CNC igwena ike itule.

CF8M bụ ihe nkedo austenitic igwe anaghị agba nchara nke ASTM A351, ASTM A743 na ASTM A744 kpuchiri. CF8M hà SS 316/F 316 na Chinese Standard 0Cr17Ni12Mo2. CF8M bụ molybdenum na-ebu mgbanwe nke CF8 alloy ma bụrụ nkedo ya na AISI 316 igwe anaghị agba nchara arụpụtara. Ọnụnọ nke molybdenum na-abawanye nguzogide corrosion n'ozuzu yana iguzogide pitting site na chlorides. A na-eji alloy eme ihe na ọnọdụ acidic na obere alkaline yana ijikwa acid citric, oxalic na phosphoric. Igwe anaghị agba nchara CF8M bụ nke ukwuu dị ka SS 316, F 316 na TP 316. Ma ha na-kọwapụtara dị iche iche ụkpụrụ, na ha chemical na mechancial Njirimara dịtụ iche kwa. A kọwapụtara CF8M na ASMT A351, ASMT A743 na ASTM A744, nke bụ maka ebumnuche nkedo naanị. A kọwapụtara SS 316 na ASTM A240 na ASTM A276, ọ bụ maka efere efere, mpempe akwụkwọ, warara ma ọ bụ igwe anaghị agba nchara. Aha ọkwa ọzọ dị ka F316, nke sitere na ASTM A182 maka naanị akụkụ adịgboroja. A ga-ahụ TP316 na ATSTM A376 maka naanị ọkpọkọ. Ngwa ndị bụ isi nke CF8M nkedo mkpuchi igwe anaghị agba nchara: impellors, propellers, casings pump, ozu valve na efere efere. Usoro ọgwụgwọ okpomọkụ maka CF8M bụ ihe ngwọta siri ike site na ikpo ọkụ karịa 1900 °F (1040 Celsius C), na-ejide oge zuru oke wee menyụọ na mmiri ma ọ bụ dị jụụ site n'ụzọ ndị ọzọ.

| Data teknụzụ nkedo itinye ego na RMC | |

| R&D | Ngwa ngwa: Solidworks, CAD, Procast, Pro-e |

| Oge ndu maka mmepe na ihe nlele: 25 ruo 35 ụbọchị | |

| Ọla ọla | Ferritic igwe anaghị agba nchara, Martensitic igwe anaghị agba nchara,Austenitic igwe anaghị agba nchara, Mmiri ozuzo ike igwe anaghị agba nchara, Duplex igwe anaghị agba nchara |

| Carbon Steel, Alloy Steel, Ngwá Ọrụ Steel, Okpomọkụ na-eguzogide ígwè, | |

| Alloy Nickle-base Alloy, Aluminom Alloy, Copper-base Alloy, Cobalt-base Alloy | |

| Ọkọlọtọ igwe | ISO, GB, ASTM, SAE, GOST EN, DIN, JIS, BS |

| Ihe eji arụ ụlọ Shell | Silica Sol (Silica nwere mmiri ozuzo) |

| Igwe mmiri (Sodium Silicate) | |

| Ngwakọta nke Silica Sol na Glass Water | |

| Nka nka | Iberibe ibu: gram 2 ruo 200 grams |

| Oke kachasị: 1,000 mm maka dayameta ma ọ bụ Ogologo | |

| Obere mgbidi: 1.5mm | |

| Ihe nkedo nkedo: Ra 3.2-6.4, Ịrụ arụrụ arụ: Ra 1.6 | |

| Nkwenye nke nkedo: VDG P690, D1/CT5-7 | |

| Nlegide nke igwe: ISO 2768-mk/IT6 | |

| Isi N'ime: Ceramic Core, Urea Core, Water Soluble Wax Core | |

| Ọgwụgwọ okpomọkụ | Normalizing, Iwe iwe, Nkwụsị, Mwepu, Ngwọta, Carburization. |

| Ọgwụgwọ elu | Nchacha, aja/mgba ọkụ, Mwepu Zinc, Plate nickel, Ọgwụgwọ Oxidition, Phosphate, Ntụ ntụ, Geormet, Anodizing |

| Nlele nha nha | CMM, Vernier Caliper, N'ime Caliper. Gage Omimi, Gage Height, Go/No go Gage, Ihe ndozi pụrụ iche |

| Nyocha kemịkalụ | Nyocha ihe mejupụtara kemịkalụ (ihe kemịkalụ 20), Nnyocha ịdị ọcha, Nnyocha redio X-ray, nyocha nke carbon-sulfur. |

| Nyocha anụ ahụ | Ntụle na-agbanwe agbanwe, Static Blancing, Mechanical Properties (Ike siri ike, Ike Mịpụta, Ike tensile), Mgbatị |

| Ike mmepụta | Ihe karịrị tọn 250 kwa ọnwa, ihe karịrị tọn 3,000 kwa afọ. |

Ngwakọta kemịkalụ nke CF8M Cast igwe anaghị agba nchara:

Carbon: 0.08 max

Manganese: 1.50 max

Silicon: 1.50 max

Sulfur: 0.040 max

Phosphorus: 0.040 max

Chromium: 18.0-21.0

Nickel: 9.0-12.0

Molybdenum: 2.0-3.0

Njirimara arụrụ arụ nke igwe anaghị agba nchara CF8M:

Ike Mgbatị: min 70 ksi (485 Mpa)

Ike Mpụta: min 30 ksi (205 Mpa)

Elongation na 2 inch. ma ọ bụ 50 mm: min 30.0%

Gịnị kpatara eji akpọ ha CF8M?

Dị ka nhọpụta ahụ si dị, mkpụrụedemede mbụ C pụtara ọrụ e zubere iji rụọ ọrụ na-eguzogide corrosion, mana mgbe ụfọdụ ọ pụtara iji CASTING n'ihi na ị ga-ahụ F 316 na ASTM A 350 (F = FORGE). Akwụkwọ ozi nke abụọ F na-egosi nso ebe alloy dị na eserese ternary iron-chromium-nickel (FeCrNi). Maka ndị ọrụ maara eserese ahụ, akwụkwọ ozi nke abụọ na-enye ihe ngosi nke ọdịnaya iron, nickel, na chromium akpọrọ aha, mana ọtụtụ mmadụ ga-enweta ozi ntinye aka na nkọwapụta ihe. Akwụkwọ ozi nke atọ na nke anọ 8M na-anọchi anya ọdịnaya carbon kacha anabatara na nkeji 0.01% (dịka ọmụmaatụ, CF8M nwere oke nke 0.08% carbon)