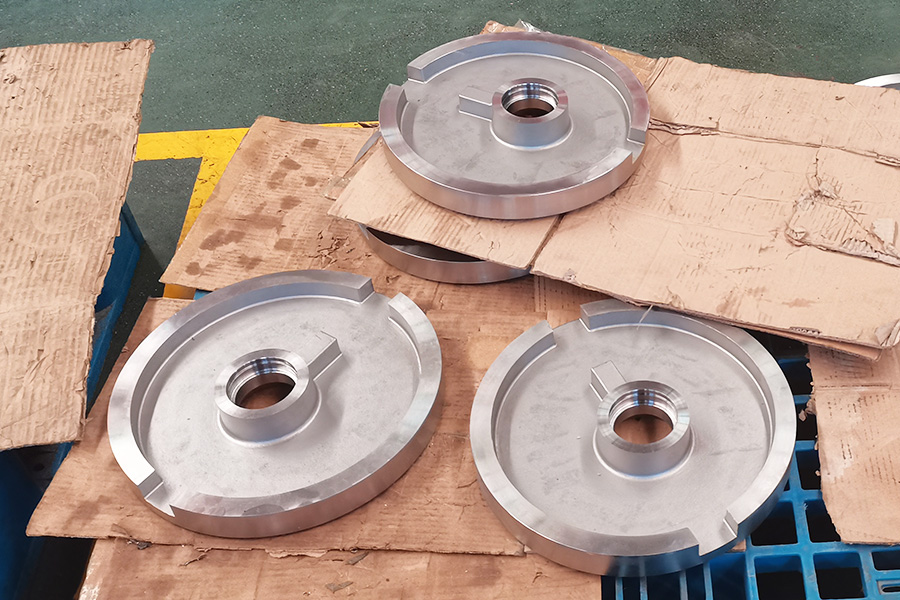

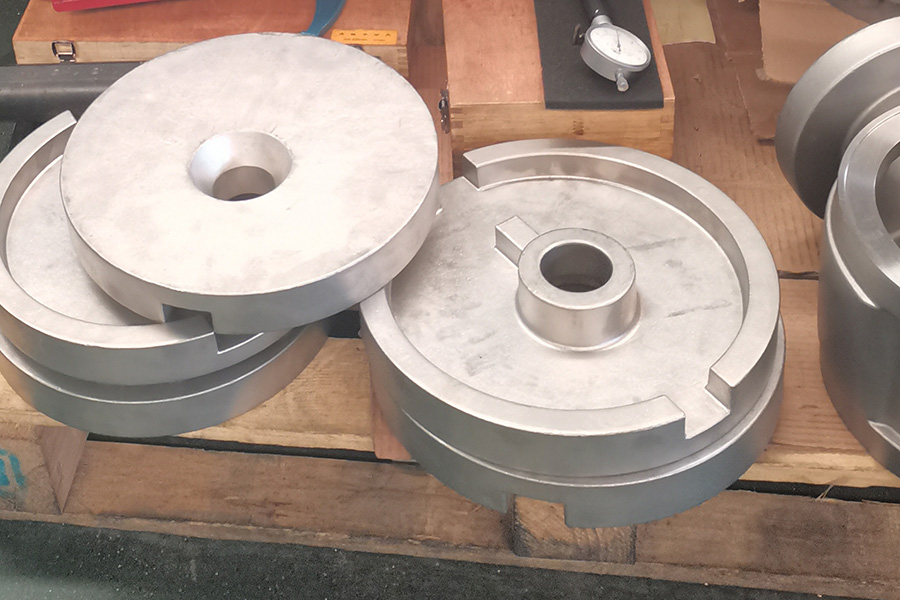

Cobalt dabeere alloy itinye ego nkedo ngwaahịa si China original foundry nwere okpomọkụ ọgwụgwọ na CNC machining ọrụ

| Ọla makaUsoro nkedo itinye egona RMC | |||

| Otu | China ọkwa | Ọkwa US | Germany ọkwa |

| Carbon ígwè | ZG15, ZG20, ZG25, ZG35, ZG45, ZG55, Q235, Q345, Q420 | 1008, 1015, 1018, 1020, 1025, 1030, 1035, 1040, 1045, 1050, 1060, 1070, WC6, WCC, WCB, WCA, LCB | 1.0570, 1.0558, 1.1191, 1.0619, 1.0446, GS38, GS45, GS52, GS60, 1.0601, C20, C25, C30, C45 |

| Alloy Alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V | 1117, 4130, 4140, 4340, 6150, 5140, WC6, LCB, Gr.13Q, 8620, 8625, 8630, 8640, H13 | GS20Mn5, GS15CrNi6, GS16MnCr5, GS25CrMo4V, GS42CrMo4, S50CrV4, 34CrNiMo6, 50CrMo4, G-X35CrMo17, 1.1131, 1.0037, 1.0122, 1.2162, 1.2542, 1.6511, 1.6523, 1.6580, 1, 3.13.7. 1.7225, 1.7227, 1.7228, 1.7231, 1.7321, 1.8519, ST37, ST52 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Ngwá Ọrụ Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Igwe na-eguzogide okpomọkụ | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX (66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Cobalt-base Alloy | UMC50, 670, Ọkwa 31 | 2,4778 | |

Alloy dabere na cobalt bụ alloy siri ike nke nwere ike iguzogide ụdị iyi dị iche iche, corrosion na oxidation dị elu. Alloys dabere na cobalt dabere na cobalt dị ka ihe bụ isi, nwere nnukwu nickel, na-eme ka ihe kemịkalụ dị ka chromium, tungsten na obere ihe dị ka molybdenum, niobium, tantalum, titanium, lanthanum, na mgbe ụfọdụ ígwè. . Dị ka ihe dị iche iche mejupụtara alloy si dị, a na-eme ka alloy dabeere na cobalt ka ọ bụrụ waya ịgbado ọkụ, a pụkwara iji ntụ ntụ mee ihe maka ịgbado ọkụ siri ike, ịgbado ọkụ, ịgbado ọkụ na usoro ndị ọzọ, a pụkwara ime ya ka ọ bụrụ nkedo. , forgings na ntụ ntụ metallurgy akụkụ. Nkewa site na ojiji njedebe, enwere ike kewaa alloys dabere na cobalt ka ọ bụrụ alloys na-eguzogide iyi, cobalt dabere na oke okpomọkụ na ihe ngwọta dabere na corrosion na-eguzogide ọgwụ. Na ọnọdụ ọrụ n'ozuzu, ha abụọ na-eguzogide iyi na oke okpomọkụ na-eguzogide ma ọ bụ na-eguzogide ọgwụ na corrosion na-eguzogide. Ụfọdụ ọnọdụ ọrụ nwekwara ike ịchọ nnukwu okpomọkụ, eyi na nguzogide corrosion n'otu oge. Ka ọnọdụ ọrụ siri ike dịkwuo mgbagwoju anya, otú ahụ ka uru nke alloys dabeere na cobalt pụta ìhè.

Njirimara nke Alloys dabere na Cobalt

Ndị isi carbides na superalloys dabere na cobalt bụ MC, M23C6 na M6C. N'ime ihe nkedo dabere na cobalt, M23C6 na-agbado n'etiti oke ọka na dendrites n'oge oyi na-adị nwayọ. N'ụfọdụ alloys, ezigbo M23C6 nwere ike mepụta eutectic na matrix γ. MC carbide ahụ buru ibu ka ọ nwee mmetụta dị ịrịba ama na dislocations, ya mere mmetụta na-ewusi ike na alloy abụghị ihe doro anya, ebe carbide chụsasịrị nke ọma na-enwe mmetụta dị ike. Carbides nke dị na oke ọka (karịsịa M23C6) nwere ike igbochi oke oke ọka, si otú a na-eme ka ike ntachi obi dịkwuo mma. The microstructure nke cobalt dabeere superalloy HA-31 (X-40) bụ a gbasasịa agbasi ike na-adọ (CoCrW) 6 C-ụdị carbide. Usoro topological nso juru n'ọnụ nke na-apụta na ụfọdụ alloys dabere na cobalt, dị ka usoro sigma na-emerụ ahụ ma na-eme ka alloy ahụ kewaa.

Nkwụsi ike nke okpomọkụ nke carbide na alloys dabeere na cobalt dị mma. Mgbe okpomọkụ na-ebili, mmụba nke mkpokọta carbide na-adị nwayọọ karịa uto nke γ na-eto eto na alloy dabeere na nickel, na okpomọkụ nke ịgbasa n'ime matriks dịkwa elu (ruo 1100 ° C). . Ya mere, mgbe okpomọkụ na-ebili, ihe mkpuchi nke cobalt Ike nke alloy n'ozuzu na-ebelata nwayọọ nwayọọ. Alloys dabere na cobalt nwere ezigbo nguzogide corrosion thermal. Ihe mere alloys dabere na cobalt ji dị elu karịa alloys dabere na nickel na nke a bụ na ebe mgbaze nke cobalt sulfide (dị ka Co-Co4S3 eutectic, 877℃) dị elu karịa nke nickel (Dịka ọmụmaatụ, Ni-Ni3S2 eutectic). (645°C) dị elu, na mgbasa nke sọlfọ na cobalt dị nnọọ ala karịa nke ahụ na nickel Ma n'ihi na ọtụtụ Alloys dabeere cobalt nwere elu chromium ọdịnaya karịa nickel dabeere alloys, ha nwere ike na-etolite a echebe oyi akwa nke alkali metal sulfate (dị ka a Cr2O3 oyi akwa nke na-corroded site Na2SO4) n'elu nke alloy Otú ọ dị, oxidation iguzogide Alloys dabere na cobalt na-adịkarị ala karịa nke alloys dabere na nickel.

Dị iche na superalloys ndị ọzọ, superalloys dabeere na cobalt adịghị eme ka usoro mmiri ozuzo nyere iwu kwadoro nke ọma na matriks ahụ, kama ọ bụ nke austenite fcc matrix nke bụ ihe ngwọta siri ike na-ewusi ike na obere obere carbides na-ekesa na matriks. Nkedo superalloys dabere na cobalt na-adabere kpamkpam na ike carbide. Kristal cobalt dị ọcha nwere ihe mkpuchi kristal hexagonal dị nso n'okpuru 417°C, nke na-agbanwe ka fcc na oke okpomọkụ. Iji gbanarị mgbanwe a n'oge a na-eji superalloys dabere na cobalt, ihe fọrọ nke nta ka ọ bụrụ Alloys niile dabere na nickel ka a na-eji nickel eme ka ọ kwụsie ike n'ihe owuwu ahụ site na okpomoku ụlọ ruo n'ebe okpomọkụ. Alloys dabere na cobalt nwere mmekọrịta nrụgide na-ekpo ọkụ dị larịị, mana na-egosi nguzogide corrosion thermal dị elu na okpomọkụ karịa 1000 Celsius C karịa oke okpomọkụ ndị ọzọ.

Ọkụ ọkụ nke Alloys dabere na Cobalt

Nha na nkesa nke irighiri carbide na oke ọka na cobalt alloys na-enwe mmetụta nke ukwuu na usoro nkedo. Iji nweta ike ntachi obi achọrọ yana njirimara ike ọgwụgwụ ọkụ nke akụkụ nkedo alloy dabere na cobalt, a ga-achịkwarịrị usoro nkedo. Alloys dabeere na cobalt chọrọ ọgwụgwọ okpomọkụ, tumadi iji chịkwaa ọdịda nke carbides. N'ihi na nkedo cobalt alloys, buru ụzọ mee elu okpomọkụ siri ike ngwọta ọgwụgwọ, na-emekarị na okpomọkụ nke ihe dị ka 1150 Celsius C, nke mere na ihe niile bụ isi carbide, gụnyere ụfọdụ MC-ụdị carbides, na-agbaze n'ime siri ike ngwọta; Mgbe ahụ, a na-eme ọgwụgwọ ịka nká na 870-980 ° C. Mee ka carbide wụsa ọzọ.

Ọkwa nkịtị nke Alloys dabere na Cobalt

Ụdị akara ule nke cobalt dabeere na elu okpomọkụ alloys bụ: 2.4778 (dị ka DIN EN 10295) Hayness 188, Haynes 25 (L-605), Alloy S-816, UMCo-50, MP-159, FSX-414, X -40, Stelite 6B, ọkwa 31, wdg, ụdị ndị China bụ: GH5188 (GH188), GH159, GH605, K640, DZ40M na ndị ọzọ.

Ngwa nke ihe nkedo Alloy dabere na Cobalt

N'ozuzu, superalloys dabere na cobalt enweghị usoro agbam ume na-ejikọta ọnụ. Ọ bụ ezie na ike na ọkara okpomọkụ dị ala (naanị 50-75% nke alloys dabeere na nickel), ha nwere ike dị elu, ezigbo ike ọgwụgwụ okpomọkụ, nkwụsị nke abrasion, mma weldability na thermal corrosion resistance n'elu okpomọkụ nke 980 ° C. Ya mere, ihe nkedo alloy dabere na cobalt dabara adaba maka imepụta vanes ndu na ntụ ntụ ntụ maka ụgbọ elu jet ụgbọ elu, turbin gas ụlọ ọrụ, turbin gas ụgbọ mmiri, na igwe mmanụ dizel, wdg.