Ihe nkedo na-eguzogide corrosion, nke a na-akpọkwa igwe anaghị agba nchara, na-ezo aka na ihe nkedo alloy nke na-egosipụta nguzogide siri ike na corrosion n'ụdị mgbasa ozi na-emebi emebi dị iche iche ma ọ bụ gburugburu ebe corrosion na ihe igwe na-arụkọ ọrụ ọnụ.

| Nlele ngwa ngwa maka igwe anaghị agba nchara Austenitic | |

| Isi ihe mejupụtara kemịkalụ | Cr,Ni,C,Mo,Cu,Si,Nb,Ti |

| Arụmọrụ | Enweghị magnetik, ịdị elu siri ike, plasticity dị elu, ike dị ala |

| Nkọwa | Igwe anaghị agba nchara na austenitic Ọdịdị na ụlọ okpomọkụ |

| akara ule ndị nnọchi anya | 304, 316, 1.4310, 1.4301, 1.4408 |

| Ịrụ ọrụ | Ọmarịcha |

| Weldability | N'ozuzu oke mma |

| Ejikarị | Igwe nri, Akụrụngwa, Nhazi kemịkalụ... wdg |

Igwe anaghị agba nchara nwere opekempe chromium ọdịnaya nke 10.5%, na-eme ka ọ na-eguzogide ọgwụ na gburugburu mmiri mmiri na-emebi emebi yana oxidation. Ọ bụ nke ukwuu corrosion eguzogide na eyi na-eguzogide ọgwụ, na-enye magburu onwe machinability, na a maara nke ọma maka aesthetic ọdịdị. Ihe nkedo ntinye ego igwe anaghị agba nchara bụ "na-eguzogide corrosion" mgbe ejiri ya na gburugburu mmiri mmiri na vapors n'okpuru 1200°F (650°C) yana "ọkụ na-eguzogide" mgbe ejiri ya karịa okpomọkụ a.

Austenitic igwe anaghị agba ncharana-ezo aka igwe anaghị agba nchara nwere ihe owuwu austenitic na ụlọ okpomọkụ. Austenitic igwe anaghị agba nchara bụ otu n'ime klaasị ise nke igwe anaghị agba nchara site crystalline Ọdịdị (yana ferritic, martensitic, duplex na ọdịda mmiri siri ike). N'ebe ụfọdụ, a na-akpọkwa igwe anaghị agba nchara 300 usoro igwe anaghị agba nchara. Mgbe nchara nwere ihe dịka 18% Cr, 8% -25% Ni, na ihe dịka 0.1% C, ọ nwere usoro austenite kwụsiri ike. Austenitic chromium-nickel igwe anaghị agba nchara gụnyere igwe anaghị agba nchara 18Cr-8Ni na igwe usoro Cr-Ni dị elu mepụtara site na ịgbakwunye ọdịnaya Cr na Ni yana ịgbakwunye Mo, Cu, Si, Nb, Ti na ihe ndị ọzọ na ndabere a. Austenitic igwe anaghị agba nchara abụghị magnetik ma nwee nnukwu ike na plasticity, mana ike ya dị ala, ọ gaghị ekwe omume iwusi ya ike site na mgbanwe oge. Enwere ike iwusi ya ike naanị site na ịrụ ọrụ oyi. Ọ bụrụ na agbakwunyere ihe ndị dị ka S, Ca, Se, Te, ọ nwere ezigbo ihe eji arụ ọrụ.

Igwe anaghị agba nchara Austenitic nwekwara ike imepụta nkedo. Iji mee ka mmiri dị nchara nke igwe a wụrụ awụ ma melite ịrụ ọrụ nkedo, ekwesịrị imezi ihe ngwakọta alloy nke ihe nkedo site n'ịba ụba ọdịnaya silicon, gbasaa oke ọdịnaya chromium na nickel, na ịbawanye oke elu nke sọlfọ na-adịghị ọcha.

Austenitic igwe anaghị agba nchara kwesịrị siri ike-solution mesoo tupu ojiji, nke mere ka jirichaa siri ike ngwọta nke dị iche iche precipitates dị ka carbides na ígwè n'ime austenite matrix, mgbe nakwa homogenizing Ọdịdị na iwepu nchegbu, ka iji hụ na magburu onwe corrosion eguzogide na n'ibu Njirimara. The ziri ezi ngwọta ọgwụgwọ usoro bụ mmiri jụrụ mgbe kpo oku na 1050 ~ 1150 ℃ (na mkpa akụkụ nwekwara ike ikuku mma). The ngwọta ọgwụgwọ okpomọkụ dabere na ogo alloying nke ígwè: Molybdenum-free ma ọ bụ obere molybdenum ígwè akara ule kwesịrị ịdị ala (≤1100 ℃), na elu alloyed akara ule dị ka 00Cr20Ni18Mo-6CuN, 00Cr25Ni22Mo2N, wdg kwesịrị ịdị elu ( 1080 ~ 1150) ℃).

Austenitic 304 igwe anaghị agba nchara efere, nke a na-ekwu na-eweta ike mgbochi nchara na corrosion iguzogide, na nwere magburu onwe plasticity na siri ike, nke dị mma maka stamping na akpụ. Na njupụta nke 7.93 g / cm3, 304 igwe anaghị agba nchara bụ igwe anaghị agba nchara, nke a makwaara dị ka 18/8 igwe anaghị agba nchara na ụlọ ọrụ. Ngwaahịa metal ya na-eguzogide okpomọkụ dị elu ma nwee ihe nhazi dị mma, n'ihi ya, a na-ejikarị ya eme ihe na ụlọ ọrụ na ụlọ ọrụ ịchọ mma na ụlọ ọrụ nri na ọgwụ.

Ọkwa nke igwe anaghị agba nchara | |||||||

| Otu | AISI | W-nkwakọba | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic na Ferritic igwe anaghị agba nchara | 420C | 1.4034 | X43Cr16 | ||||

| 440 B/1 | 1.4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 cr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 crS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 cr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 cr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CRNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CRMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Austenitic igwe anaghị agba nchara | 304 | 1.4301 | X5 CRNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 KrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CRNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CRNi 18 9 | 304 S31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CRNi 18 9 | 304 S31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316 Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S24 | - | - | X16 KrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex igwe anaghị agba nchara | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

Ngwa igwe anaghị agba nchara maka nkedo itinye ego, Usoro nkedo wax furu efu:

- • Ígwè isi awọ: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10-GG40.

- • Iron Ductile ma ọ bụ Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

- • Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

- • Alloys ígwè: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo ... wdg na arịrịọ.

- • Igwe anaghị agba nchara: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 na ndị ọzọ igwe anaghị agba nchara ọkwa.

- • Brass, Red Copper, Bronze ma ọ bụ ọla kọpa ndị ọzọ dabere na ọla: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

- • Akụrụngwa ndị ọzọ dị ka ihe pụrụ iche chọrọ ma ọ bụ dị ka ASTM, SAE, AISI, ACI, DIN, EN, ISO, na GB ụkpụrụ.

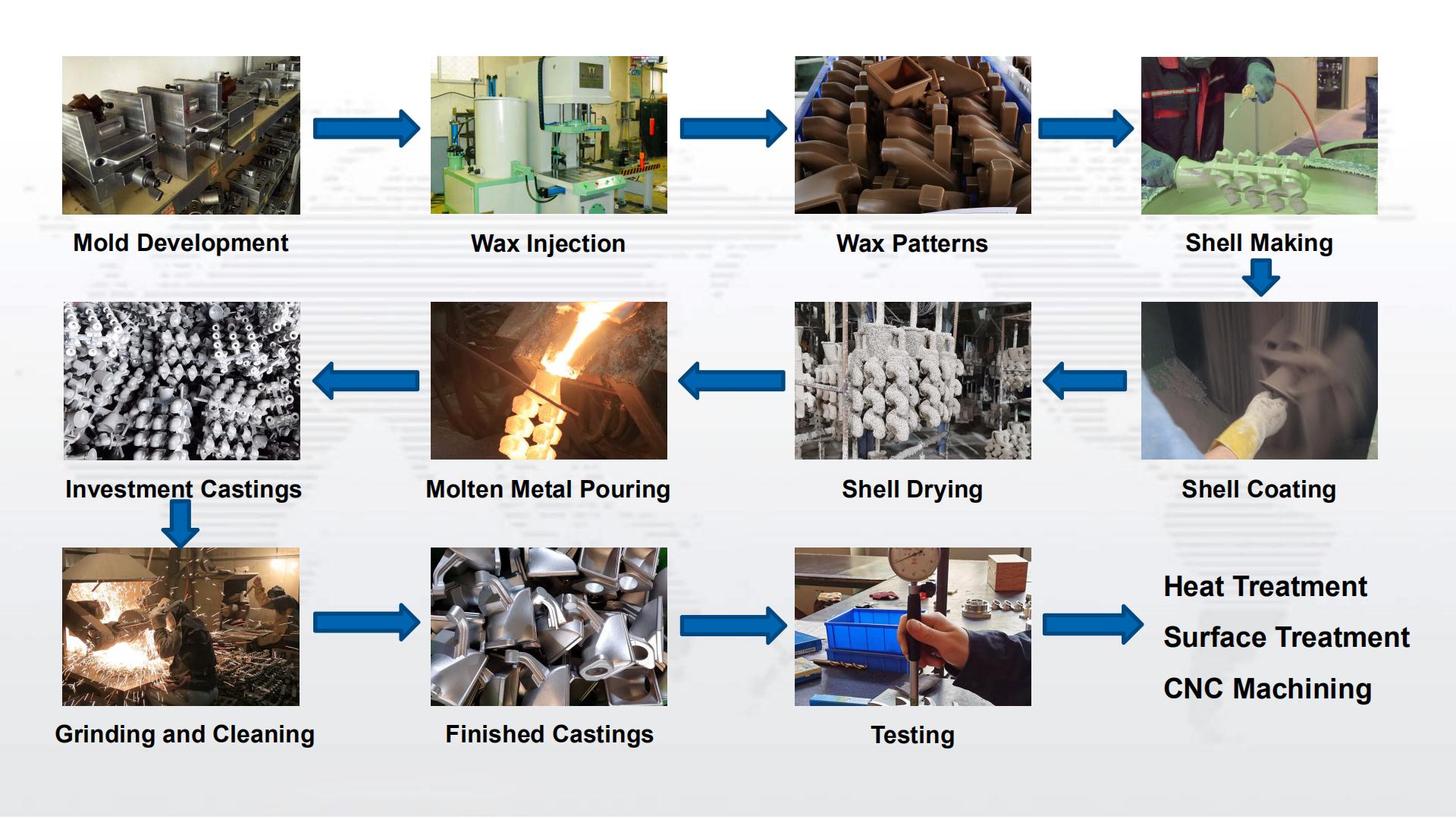

Usoro ndị dị na usoro a ma ọ bụ nkedo wax furu efu bụ:

- • Mepụta ụkpụrụ wax ma ọ bụ oyiri

- • Gbasaa ụkpụrụ wax

- • Tinye ego n'ụkpụrụ wax

- • Wepu ụkpụrụ wax site n'ịkpọ ya ọkụ (n'ime ọkụ ọkụ ma ọ bụ na mmiri ọkụ) iji mepụta ọkpụkpụ.

- • Na-amanye ígwè a wụrụ awụ n'ime ihe ebu

- • Ịjụ oyi na ịkwado

- • Wepu sprue na nkedo

- • Mechaa ma kpochaa nkedo itinye ego emechara

Ọgwụgwọ ọkụ nke AISI 316 igwe anaghị agba nchara:

Kpoo ọkụ ruo 1900°F (1040°C) opekempe, na-ejide oge zuru oke, menyụọ na mmiri ma ọ bụ dị jụụ site n'ụzọ ndị ọzọ. AISI 316 ha nhata CF8M/F316 na ọkọlọtọ Chinese 0Cr17Ni12Mo2. AISI 314 bụ molybdenum na-ebu mgbanwe nke AISI 304 alloy ma bụrụ ihe nkedo nke arụrụ arụ ọrụ CF8M igwe anaghị agba nchara. Ọnụnọ nke molybdenum na-abawanye nguzogide corrosion n'ozuzu yana iguzogide pitting site na chlorides. A na-eji alloy eme ihe na ọnọdụ acidic na obere alkaline yana ijikwa acid citric, oxalic na phosphoric.