OEM omenala brass nkedo flange na ndị ọzọ itinye ego nkedo ọla components na-arụ ọrụ dị mkpa dị ka ibu bushings, gia, valvụ na mgbapụta ozu, mmiri ọkpọkọ na ndị ọzọ.ụlọ ọrụ igwenke chọrọ arụmọrụ nke nguzogide corrosion na iyi nguzogide.

Dị ka ọla kọpa na-ejikarị ọla kọpa eme ihe, enwere ike ịmepụta bras ka ọ bụrụ akụkụ nkedo dị mgbagwoju anya, na-eme ka ha dị mma maka usoro ntinye ego. Mgbanwe ọnụ ahịa na-adị mgbe niile nwere ike ime ka ihe ndị a dị oke ọnụ ahịa, na-eme ka mkpofu dị oke ọnụ, ọkachasị mgbe ị na-atụle machining CNC na / ma ọ bụ imepụta dị ka usoro nrụpụta iji mepụta gị.akụkụ nkedo. Agbanyeghị, a naghị atụkarị ọla kọpa dị ọcha. Nkedo ọla nwere akụrụngwa dị elu karịa ọla kọpa, mana ọnụ ahịa ya dị ala karịa ọla kọpa.

Brass bụ alloy mejupụtara ọla kọpa na zinc. A na-akpọ Brass nke ọla kọpa na zinc mejupụtara bụ ọla nkịtị. Ọ bụrụ na ọ bụ ụdị alloys dị iche iche mejupụtara ihe karịrị ihe abụọ, a na-akpọ ya ọla pụrụ iche. Brass bụ ọla kọpa nwere zinc dị ka isi ihe. Ka ọdịnaya zinc na-abawanye, ike na plasticity nke alloy na-abawanye nke ukwuu, mana akụrụngwa akụrụngwa ga-ebelata nke ukwuu mgbe ọ gafere 47%, yabụ ọdịnaya zinc nke ọla bụ ihe na-erughị 47%. Na mgbakwunye na zinc, ọla nkedo na-enwekarị ihe ndị na-ekekọta ihe dịka silicon, manganese, aluminum, na lead.

Ihe Brass na Bronze Anyị na-atụba

- • Ọkọlọtọ China: H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2

- • USA Standard: C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100

- • Ụkpụrụ Europe: CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5

| Metal na Alloys dị maka usoro nkedo & nrụpụta dị iche iche

| ||

| Usoro mmepụta | Ihe onwunwe | |

| Nkedo ájá | Agba aja aja nkedo | Igwe anaghị agba nchara, igwe anaghị agba nchara, igwe anaghị agba nchara, igwe anaghị agba nchara, igwe anaghị agba nchara, igwe anaghị agba nchara, Alloy Alloy, Aluminium Alloy, Brass, wdg. |

| Nkedo nkedo aja nke ekpuchiri resin | ||

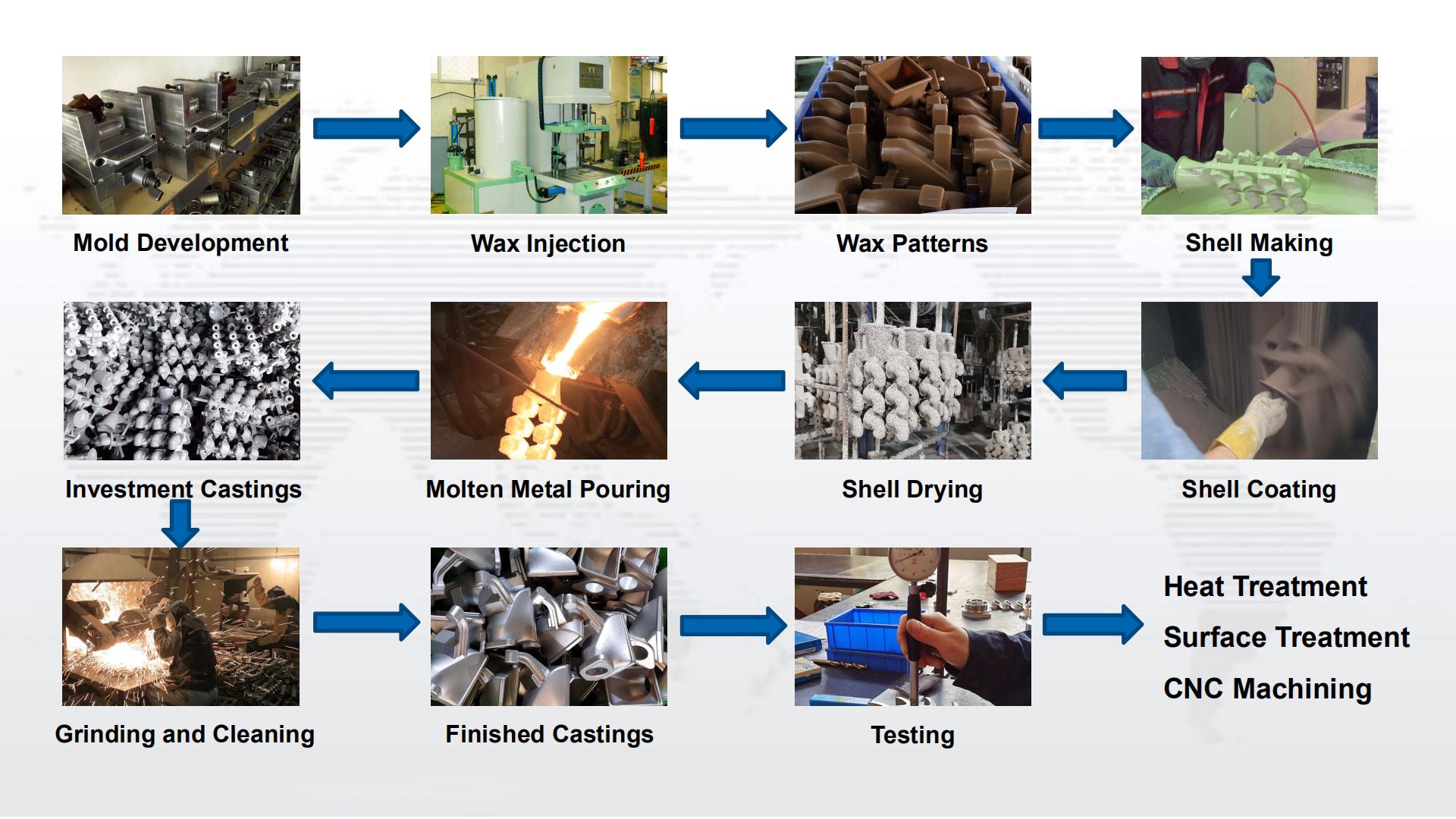

| Nkedo itinye ego (nkedo wax furu efu) | Mmiri iko itinye ego nkedo | Carbon Steel, Alloy Steel, igwe anaghị agba nchara, Duplex igwe anaghị agba nchara, Cast Iron, Brass, Aluminom na ndị ọzọ alloys. |

| Ọnụ ego nke Silica Sol Investment Casting | ||

| Nkedo ụfụfụ efu efu | Ígwè nkedo Ductile / isi awọ nkedo ígwè | |

| ASTM 60-40-18 / 65-45-12 / 80-55-06 / 100-70-03 | ||

| Carbon ígwè, Hi-Mn ígwè, Hi-Cr ígwè | ||

| Iron Austempering Ductile Iron (ADI) | ||

| Igwe na-eguzogide okpomọkụ / Yiri ígwè na-eguzogide | ||

| Nkedo Vacuum (nkedo usoro V) | Iron Ductile GGG 40 ruo GGG 80/ Iron isi awọ | |

| ASTM 60-40-18 / 65-45-12 / 80-55-06 / 100-70-03 | ||

| Carbon ígwè, Hi-Mn ígwè, Hi-Cr ígwè | ||

| Iron ductile na-ekpo ọkụ | ||

| Igwe anaghị agba nchara / Yiri igwe anaghị agba nchara / igwe anaghị agba nchara | ||

| Na-akpụ akpụ | Mepee Forging | Igwe anaghị agba nchara, Carbon Steel, Alloy Steel, Brass, Aluminom |

| anwụ Forging | ||

| Nyefee Forging | ||

| Nkedo anwụ | Nnukwu nrụgide anwụ nkedo | Aluminom, Zinc, Brass |

| Nrụgide dị ala anwụ nkedo | ||

| Nrụgide ike ndọda anwụ nkedo | ||

| Ọrụ ọgwụgwọ elu | Mkpuchi ntụ ntụ, Anodization, Electrophotesis, Chrome Plating, Painting, Sand blasting, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, Geormet, Zintek, wdg. | |

| Ọrụ CNC Precision Machining | Ịkụ ihe, igwe-egwe ọka, ntugharị, ịsọpụrụ, ịkwọ ụgbọ mmiri, na-agwụ ike, ịkụ aka, Waya Electrode ịkpụ, egweri ... wdg. | |

| Nyocha na njikwa ogo | Spectrum Analyzer, CMM, Onye Nleba Obi Ike, Onye Nleba Ike Tensile, Yild Strentgh Testor, Onye Nleba Nrụgide, Carbon Sulfur Analyzer, Metallurgical Microscopy, Press Force Tester... wdg. | |