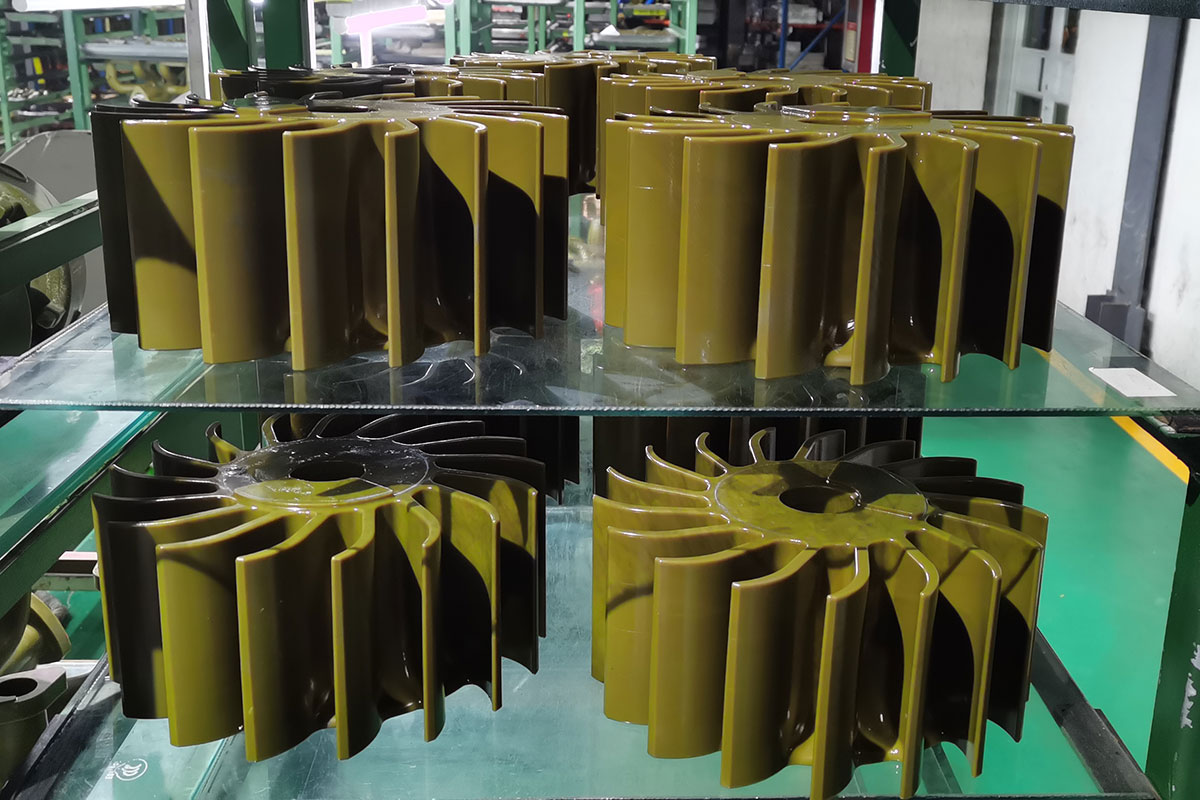

China OEM omenala igwe anaghị agba nchara impeller siteUsoro ntinye ntinye ego furu efu.

Ihe mgbakwasị ụkwụ nke ihe nkedo nickel-base ma ọ bụ igwe anaghị agba nchara bụ chromium, nickel, na molybdenum (ma ọ bụ "moly"). Akụkụ atọ ndị a ga-ekpebi nhazi ọka nke ihe nkedo na ihe eji arụ ọrụ ma bụrụ ihe enyemaka n'ikike nkedo ahụ iji luso okpomọkụ, iyi, na corrosion ọgụ.

Igwe anaghị agba nchara nwere opekempe chromium ọdịnaya nke 10.5%, na-eme ka ọ na-eguzogide ọgwụ na gburugburu mmiri mmiri na-emebi emebi yana oxidation. Agbanyeghị, nke a abụghị ihe zuru oke. Ntinye ego igwe anaghị agba ncharaihe nkedo bụ "na-eguzogide corrosion" mgbe ejiri ya na gburugburu mmiri mmiri na vapors n'okpuru 1200°F (650°C) yana "ọkụ na-eguzogide" mgbe ejiri ya karịa okpomọkụ a.

Uru nke akụrụngwa nkedo itinye ego:

- Magburu onwe ma dị ire ụtọ elu imecha

- Nkwenye akụkụ siri ike.

- Ụdị mgbagwoju anya na mgbagwoju anya nwere mgbanwe imewe

- Ikike ịwụ mgbidi ndị dị mkpa ya mere ihe nkedo dị ọkụ

- Nhọrọ sara mbara nke nkedo ọla na alloys (ferrous na ndị na-abụghị igwe)

- Ọ dịghị mkpa ka Draft na ebu imewe.

- Belata mkpa nke abụọ machining.

- obere ihe mkpofu.

| Ngwa makaNkedo itinye egoHazie naỤlọ ọrụ RMC | |||

| Otu | China ọkwa | Ọkwa US | Germany ọkwa |

| Ferritic igwe anaghị agba nchara | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic igwe anaghị agba nchara | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic igwe anaghị agba nchara | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404.4.1. 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Mmiri ozuzo na-eme ka igwe anaghị agba nchara | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex igwe anaghị agba nchara | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Ngwá Ọrụ Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Igwe na-eguzogide okpomọkụ | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX (66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Aluminom Alloy | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Alloy ọla kọpa | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-base Alloy | UMC50, 670, Ọkwa 31 | 2,4778 | |

| anabata nnabata nke itinye ego | |||

| Inches | Millimeters | ||

| Akụkụ | Ndidi | Akụkụ | Ndidi |

| Ruo 0,500 | ±.004" | Ruo 12.0 | ± 0.10mm |

| 0.500 ruo 1.000" | ±.006" | 12.0 ruo 25.0 | ± 0.15mm |

| 1.000 ruo 1.500” | ±.008" | 25.0 ruo 37.0 | ± 0.20mm |

| 1.500 ruo 2,000" | ±.010" | 37.0 ruo 50.0 | ± 0.25mm |

| 2.000 ruo 2.500” | ±.012" | 50.0 ruo 62.0 | ± 0.30mm |

| 2.500 ruo 3.500" | ±.014" | 62.0 ruo 87.0 | ± 0.35mm |

| 3.500 ruo 5,000" | ±.017" | 87.0 ruo 125.0 | ± 0.40mm |

| 5.000 ruo 7.500” | ±.020" | 125.0 ruo 190.0 | ± 0.50mm |

| 7.500 ruo 10,000" | ±.022" | 190.0 ruo 250.0 | ± 0.57mm |

| 10.000 ruo 12.500" | ±.025" | 250.0 ruo 312.0 | ± 0.60mm |

| 12.500 ruo 15.000 | ±.028" | 312.0 ruo 375.0 | ± 0.70mm |