Ụlọ valvụ omenala nke igwe anaghị agba nchara duplex mepụtara site na ntinye ntinye ego sitere na China na-eji ihe nkedoigwe, ọgwụgwọ okpomọkụ, na ọrụ ọgwụgwọ elu.

Ihe nkedo RMCnkenke nkedo ígwè akụkụnke na-ezute ma ọ bụ gafere atụmanya ndị ahịa. Nkedo itinye ego na wax furu efu na-enye anyị ohere imepụtangwaahịa nkedo igwe anaghị agba ncharadị obere dị ka iri iri nke gram na nnukwu dị ka iri puku kwuru iri kilogram, n'ụdị dị iche iche nke ferrous na-abụghị ígwè alloys na na pụrụ iche akụkụ ziri ezi.

Usoro ntinye ntinye ego nke wax furu efu na-arụpụta ihe nkedo dị nso na ụdị net nke na-achọkarị obere igwe ma ọ bụ enweghị mgbakwunye ọzọ. Emecha ya dịkwa mma karịa nke a na-enweta site na usoro nkedo ma ọ bụ nrụpụta ndị ọzọ. Ike na ịdịte aka nke akụkụ nkedo na-eme onwe ha ka ha dị mma maka ngwa nguzogide dị elu na-achọ ọtụtụ nde okirikiri.

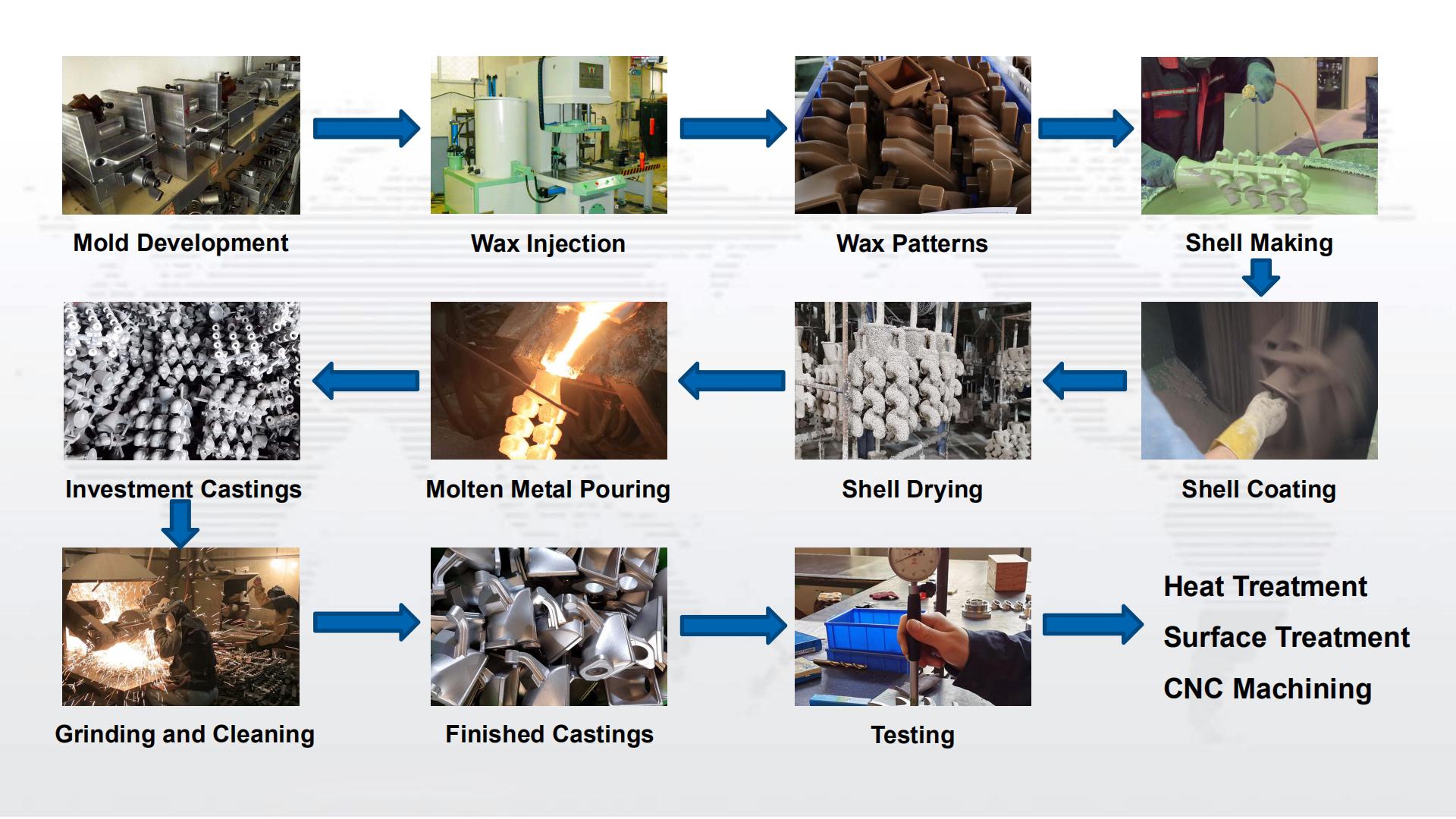

Usoro nke Usoro ntinye ego:

N'oge usoro nkedo itinye ego, a na-eji ihe seramiiki kpuchie ụkpụrụ wax, nke, mgbe ọ gbasiri ike, na-anabata geometry dị n'ime nke nkedo achọrọ. N'ọtụtụ oge, a na-atụkọta ọtụtụ akụkụ ọnụ maka ịrụ ọrụ dị elu site na ijikọta usoro wax n'otu n'otu na osisi wax etiti a na-akpọ sprue. A na-agbaze wax si n'ụkpụrụ ahụ - ya mere a na-akpọkwa ya dị ka usoro wax furu efu - a na-awụsa ígwè a wụrụ awụ n'ime oghere. Mgbe ígwè ahụ siri ike, a na-amapụ ihe ọkpụkpụ seramiiki ahụ, na-ahapụ ọdịdị net dị nso nke nkedo a chọrọ, na-esote imecha, nyocha na nkwakọ ngwaahịa.

Duplex igwe anaghị agba nchara (DSS) na-ezo aka igwe anaghị agba nchara nwere ferrite na austenite nke ọ bụla na-aza ajụjụ ihe dị ka 50%. N'ozuzu, ọdịnaya nke obere usoro kwesịrị ịdịkarịa ala 30%. N'ihe gbasara ọdịnaya C dị ala, ọdịnaya Cr bụ 18% ruo 28%, yana ọdịnaya Ni bụ 3% ruo 10%. Ụfọdụ igwe anaghị agba nchara duplex nwekwara ihe ndị na-eme ka alloying dị ka Mo, Cu, Nb, Ti, na N.

Dị ọkwa nke duplex igwe anaghị agba nchara na RMC Nkedo Foundry: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890 9A 5A 8A 9A 995 1B, A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

DSS nwere njirimara igwe anaghị agba nchara austenitic na ferritic. N'iji ya tụnyere ferrite, ọ nwere plasticity dị elu na ductility, enweghị ụlọ okpomọkụ na-egbuke egbuke, ma na-eme ka nguzogide corrosion intergranular na ịrụ ọrụ ịgbado ọkụ, ebe ọ ka na-ejigide brittleness, elu thermal conductivity, na superplasticity dị ka ferrite igwe anaghị agba nchara. Tụnyere ya na igwe anaghị agba nchara austenitic, DSS nwere ike dị elu yana nkwụsi ike nke ukwuu maka corrosion intergranular na corrosion nrụgide chloride. Igwe anaghị agba nchara duplex nwere nguzogide corrosion nke ọma ma bụrụkwa igwe anaghị agba nchara na-echekwa nickel.

| Ọkwa nke igwe anaghị agba nchara | |||||||

| Otu dị iche iche | AISI | W-nkwakọba | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic na Ferritic igwe anaghị agba nchara | 420C | 1,4034 | X43Cr16 | ||||

| 440 B/1 | 1,4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 cr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 crS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 cr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 cr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CRNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CRMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Austenitic igwe anaghị agba nchara | 304 | 1.4301 | X5 CRNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 KrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CRNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CRNi 18 9 | 304 S31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CRNi 18 9 | 304 S31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316 Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S24 | - | - | X16 KrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex igwe anaghị agba nchara | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

▶ Ọla ọla na igwe anaghị agba nchara makaNkedo itinye ego, Usoro nkedo wax furu efu:

• Ígwè isi awọ: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10-GG40.

• Iron Ductile ma ọ bụ Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

• Alloys ígwè: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo ... wdg na arịrịọ.

• Igwe anaghị agba nchara: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 na ndị ọzọ igwe anaghị agba nchara ọkwa.

• Brass, Red Copper, Bronze ma ọ bụ ọla kọpa ndị ọzọ dabere na ọla: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Akụrụngwa ndị ọzọ dị ka ihe pụrụ iche chọrọ ma ọ bụ dị ka ASTM, SAE, AISI, ACI, DIN, EN, ISO, na GB ụkpụrụ.

▶ Ikike nkeỤlọ ọrụ nkedo itinye ego

• Oke kachasị: 1,000 mm × 800 mm × 500 mm

• Oke arọ: 0,5 n'arọ - 100 n'arọ

• Ike kwa afọ: tọn 2,000

• Ihe nkwekọ maka ụlọ Shell: Silica Sol, Glass Water na ngwakọta ha.

| Ọrụ | Nkọwa |

| Ọrụ ọgwụgwọ elu | Mkpuchi ntụ ntụ, Anodization, Electrophotesis, Chrome Plating, Painting, Sand blasting, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, Geormet, Zintek, wdg. |

| Ọrụ CNC Precision Machining | Ịkụ ihe, igwe-egwe ọka, ntugharị, ịsọpụrụ, ịkwọ ụgbọ mmiri, na-agwụ ike, ịkụ aka, Waya Electrode ịkpụ, egweri ... wdg. |

| Nyocha na njikwa ogo | Spectrum Analyzer, CMM, Onye Nleba Obi Ike, Onye Nleba Ike Tensile, Yild Strentgh Testor, Onye Nleba Nrụgide, Carbon Sulfur Analyzer, Metallurgical Microscopy, Press Force Tester... wdg. |