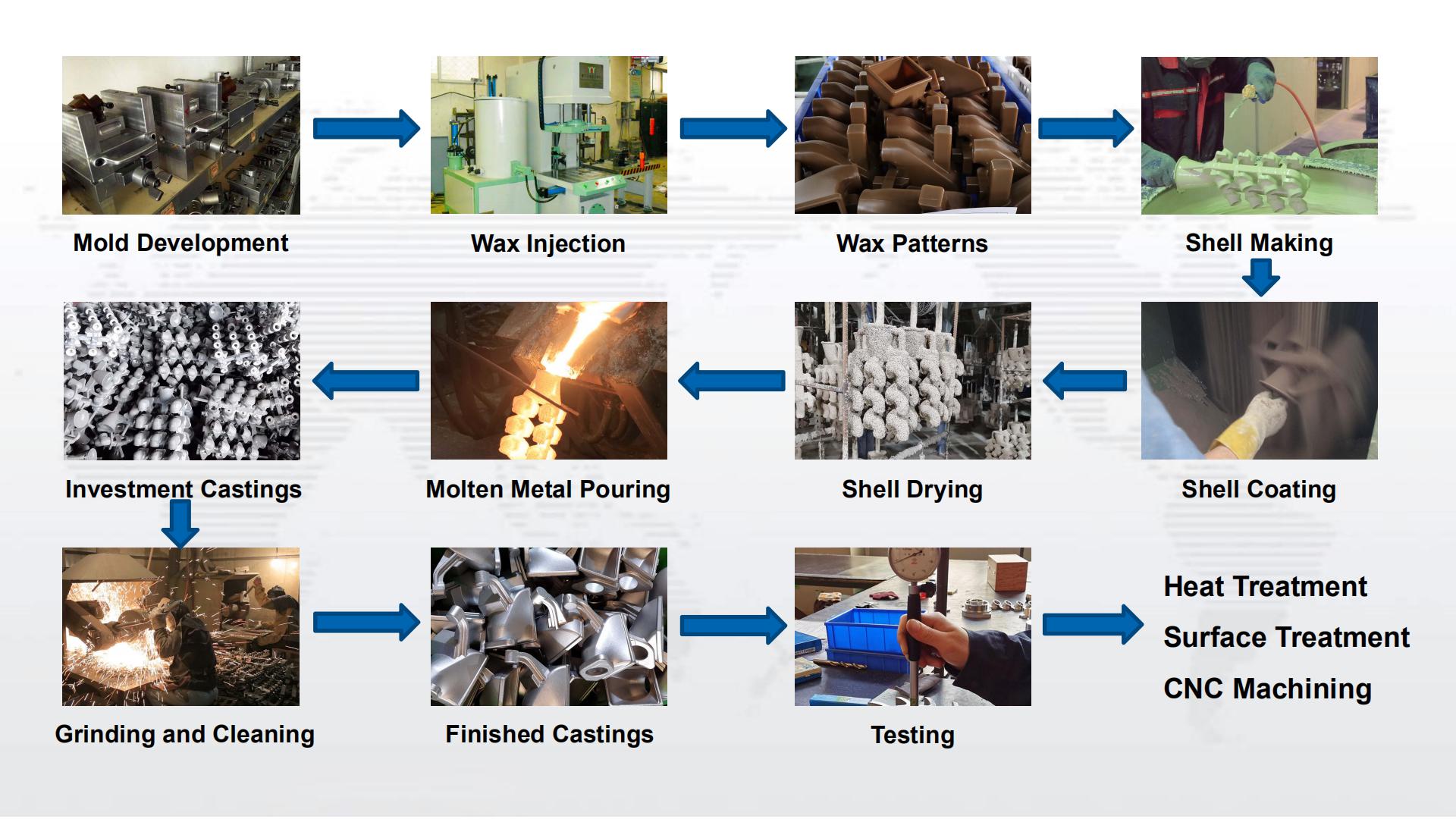

Omenala OEMduplex igwe anaghị agba nchara furu efu nkedona ọgwụgwọ okpomọkụ, ọgwụgwọ elu, CNC machining na ule ọrụ sitere n'aka otu onye na-eweta ngwaahịa na China

RMC Foundry nwere ike izute nkọwapụta ihe dịka ASTM, SAE, AISI, ACI, DIN, EN, ISO, GOST na GB ụkpụrụ. Anyị nwere ihe karịrị 100 dị iche iche ferrous na ndị na-abụghị ígwè alloys nke anyị ji atụdo akụkụ site na mgbagwoju imewe. Akụkụ akụkụ anyị na geometrically mgbagwojuihe nkedo itinye egoa na-emepụta ka ọ bụrụ ụgbụ, na-ebelata mkpa maka nhazi nke abụọ.

Duplex igwe anaghị agba nchara (DSS) na-ezo aka igwe anaghị agba nchara nwere ferrite na austenite nke ọ bụla na-aza ajụjụ ihe dị ka 50%. N'ozuzu, ọdịnaya nke obere usoro kwesịrị ịdịkarịa ala 30%. N'ihe gbasara ọdịnaya C dị ala, ọdịnaya Cr bụ 18% ruo 28%, yana ọdịnaya Ni bụ 3% ruo 10%. Ụfọdụ igwe anaghị agba nchara duplex nwekwara ihe ndị na-eme ka alloying dị ka Mo, Cu, Nb, Ti, na N.

DSS nwere njirimara igwe anaghị agba nchara austenitic na ferritic. N'iji ya tụnyere ferrite, ọ nwere plasticity dị elu na ductility, enweghị ụlọ okpomọkụ na-egbuke egbuke, ma na-eme ka nguzogide corrosion intergranular na ịrụ ọrụ ịgbado ọkụ, ebe ọ ka na-ejigide brittleness, elu thermal conductivity, na superplasticity dị ka ferrite igwe anaghị agba nchara.

Tụnyere ya na igwe anaghị agba nchara austenitic, DSS nwere ike dị elu yana nkwụsi ike nke ukwuu maka corrosion intergranular na corrosion nrụgide chloride. Igwe anaghị agba nchara duplex nwere nguzogide corrosion nke ọma ma bụrụkwa igwe anaghị agba nchara na-echekwa nickel.

Ngwá ọrụ anyị kachasị elu na njikwa usoro akpaaka na-enye ohere maka nkwado na-agbanwe agbanwe na nke a na-emegharị dịka ± 0.1 mm. Enwere ike imepụta ihe nkedo anyị n'ogo buru ibu - ha nwere ike ịdị obere ka 10 mm ogologo x 10 mm n'obosara x 10 mm n'ịdị elu ma tụọ ihe ruru 0.01 n'arọ, ma ọ bụ ihe ruru 1000 mm n'ogologo ma tụọ ihe ruru. 100 n'arọ.

Na RMC Foundry, anyị na-anya isi n'inye ndị ahịa anyị ọrụ kachasị mma site na mmalite ruo n'isi. Ọrụ anyị gụnyere:

- - Nhazi ngwá ọrụ n'ime ụlọ na ike nrụpụta.

- - Prototype mmepe.

- - Usoro nyocha na mmepe.

- - Nrụpụta mgbanwe.

- - Ikike na ule.

- - Ọgwụgwọ okpomọkụ

- - Ọgwụgwọ elu

- - Ike nrụpụta outsourcing