Nkedo isi awọ omenalaihe nkedo sheina ọrụ nkeọgwụgwọ okpomọkụna ọgwụgwọ elu.

Nkedo ịkpụzi sheiusoro a na-akpọkwa usoro nkedo resin ájá ekpuchiburu ụzọ, ihe nkedo ịkpụzi shei na-ekpo ọkụ ma ọ bụ usoro nkedo isi. Isi ihe a na-akpụzi bụ ájá phenolic resin nke e kpuchiri ya nke ọma, nke dị ọnụ karịa ájá akwụkwọ ndụ akwụkwọ ndụ na ájá resin furan. Ọzọkwa, a pụghị imegharị ájá a.

Furan resin onwe-hardening ájá usoro nhazi nkedo (nobake usoro) na-eji akwa resin mkpuchi aja na-emepụta ihe nkedo ebu. Mgbe agwakọtachara ájá mbụ (ma ọ bụ ájá eweghachitere), mmiri mmiri furan resin na mmiri na-akpali akpali ọbụna, na-ejuputa ha n'ime igbe isi (ma ọ bụ igbe ájá), wee kwesie ya ike ka ọ bụrụ ebu ma ọ bụ ebu na igbe isi (ma ọ bụ ájá). igbe) na ụlọ okpomọkụ. Mgbe ahụ, e hiwere ihe nkedo ma ọ bụ ihe nkedo, nke a na-akpọ igbe ịkpụzi oyi-isi nke onwe (isi), ma ọ bụ usoro nkedo onwe (isi).

N'ihi na a na-akpụ akpụ ahụ n'ime ụlọ na-ekpo ọkụ na ọ dịghị mkpa ikpo ọkụ, nkedo ájá na-ejide onwe ya ka a na-akpọkwa usoro nkedo enweghị achịcha. Enwere ike ikewa usoro nke siri ike nke onwe ya gaa na resin furan acid-catalyzed na usoro phenolic resin sand nke onwe ya, usoro urethane resin sand nke onwe na usoro phenolic monoester onwe-hardening.

Dị ka igbe oyi na-eme ka onwe ya sie ike, ájá resin furan bụ nke mbụ na nke a na-ejikarị eme ihe ugbu a n'ebe a na-emepụta ihe ndị China. Ọnụ ego resin agbakwunyere na ájá ịkpụzi na-abụkarị 0.7% ruo 1.0%, na ọnụ ọgụgụ resin agbakwunyere na isi ájá bụ 0.9% ruo 1.1%. Ọdịnaya nke aldehyde efu na resin furan dị n'okpuru 0.3%, ụfọdụ ụlọ ọrụ agbadala n'okpuru 0.1%. N'ebe a na-emepụta ihe na China, ájá na-agbapụta onwe ya na-esi ísì ụtọ eruola ọkwa mba ụwa n'agbanyeghị usoro mmepụta na ọdịdị elu nke nkedo.

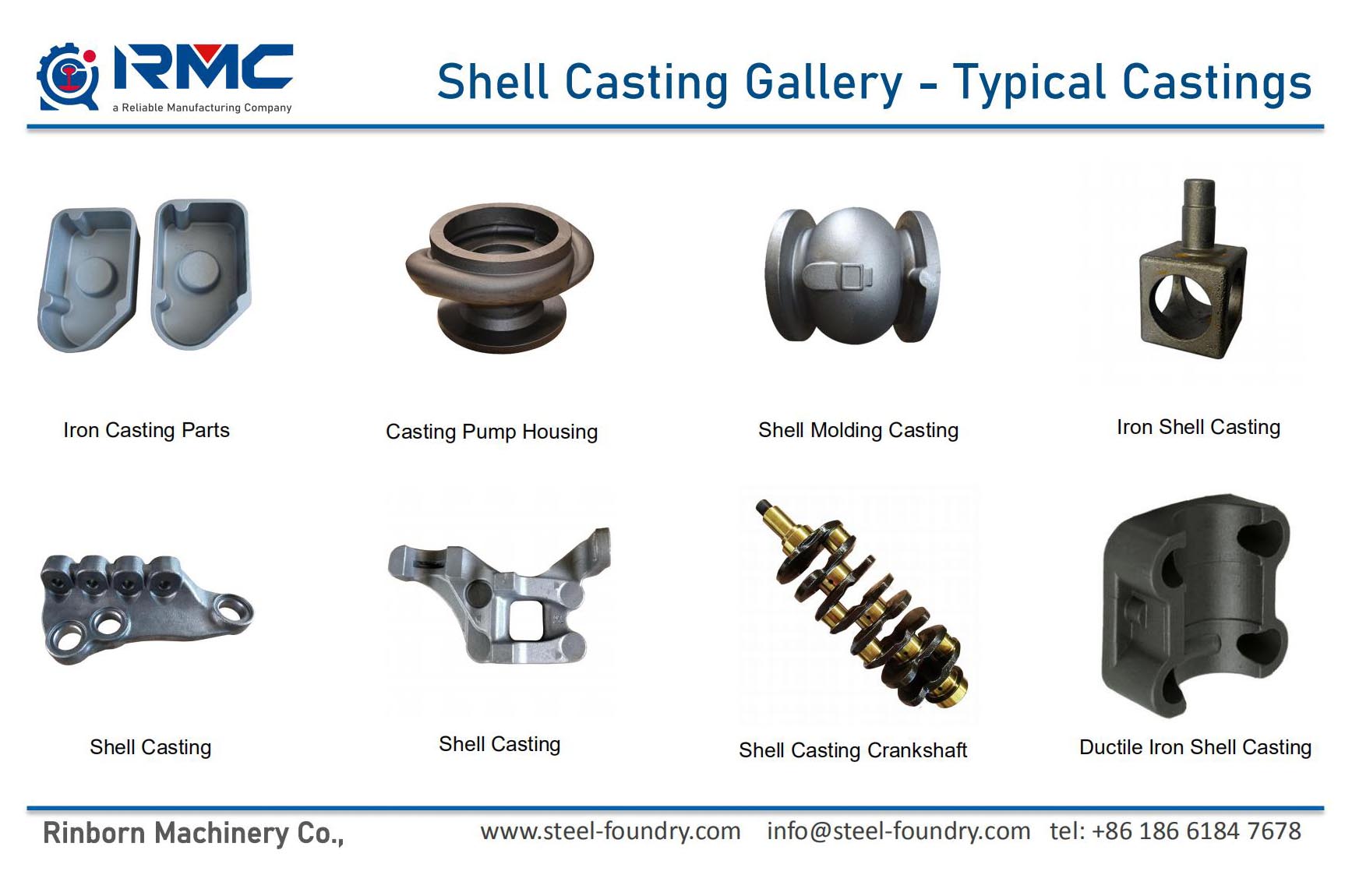

Ígwè isi awọ, ma ọ bụ nkedo isi awọ, bụ ụdị ígwè nkedo nke nwere graphite microstructure. A na-akpọ ya aha n'ihi agba isi awọ nke mgbaji ọ na-etolite. A na-eji ígwè nkedo isi awọ eme ihe maka ụlọ ebe nkwekọ nke akụkụ ahụ dị mkpa karịa ike nkwụsị ya, dị ka ihe mgbochi cylinder nke ime ụlọ, ụlọ mgbapụta, valvụ, igbe eletrik, ihe nrịbama na ihe nkedo ịchọ mma. A na-ejikarị ịdị elu okpomọkụ nke ihe nkedo isi awọ eme ihe na ikike isi a kapịrị ọnụ iji mee ihe nkedo ígwè na rotors breeki diski.

Ngwakọta kemịkalụ a na-ahụkarị iji nweta microstructure eserese bụ 2.5 ruo 4.0% carbon yana 1 ruo 3% silicon site n'ịdị arọ. Graphite nwere ike were 6 ruo 10% nke olu isi awọ. Silicon dị mkpa iji mee ígwè isi awọ n'adịghị ka ígwè nkedo na-acha ọcha, n'ihi na silicon bụ ihe na-eme ka ọkpụkpụ na-eme ka ọ dị ike na nkedo ígwè, nke pụtara na ọ na-enyere alloy aka ịmepụta graphite kama ịbụ ígwè carbide; na 3% silicon ọ fọrọ nke nta ka ọ bụrụ na ọ dịghị carbon a na-ejikọta ya na ígwè.

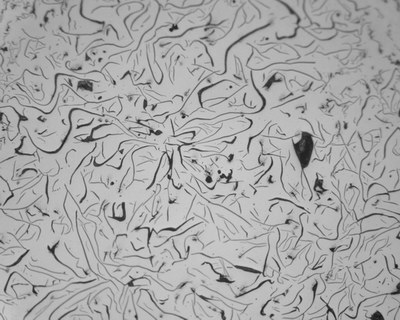

Grafite na-ewere ọdịdị nke flake akụkụ atọ. Na akụkụ abụọ, dị ka elu na-egbuke egbuke ga-apụta n'okpuru microscope, flakes graphite na-apụta dị ka ahịrị dị mma. Atụmatụ nke flakes na-arụ ọrụ dị ka ọkwa dị adị; ya mere, ọ na-agbaji agbaji. Ọnụnọ nke flakes graphite na-eme ka Iron Grey dị mfe machinable ka ha na-agbawa ngwa ngwa gafee flakes graphite. Ígwè isi awọ nwekwara ezigbo ike ime ihe n'ihi ya, a na-ejikarị ya eme ihe dị ka ntọala maka ịkwanye ngwá ọrụ igwe.

Njirimara arụrụ arụ nke Ígwè nkedo isi awọ | |||||||

| Ihe dị ka DIN EN 1561 si kwuo | tụọ | Nkeji | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | EN-JL 1030 | EN-JL 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Ike ọdụdọ | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Ike Mpụta | Rp0,1 | MPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Ike elongation | A | % | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 |

| Ike mkpakọ | σdB | MPa | 600 | 720 | 840 | 960 | 1080 |

| 0,1% Ike mkpakọ | σd0,1 | MPa | 195 | 260 | 325 | 390 | 455 |

| Ike Flexural | σbB | MPa | 250 | 290 | 340 | 390 | 490 |

| Schuifspanning | σaB | MPa | 170 | 230 | 290 | 345 | 400 |

| Nsogbu nrụgide | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Modul nke elasticity | E | GPA | 78-103 | 88-113 | 103-118 | 108-137 | 123-143 |

| Nọmba nsi | v | - | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| Brinell siri ike | HB | 160-190 | 180-220 | 190-230 | 200 - 240 | 210-250 | |

| Ịdị ike | σbW | MPa | 70 | 90 | 120 | 140 | 145 |

| Mgbanwe nrụgide na nrụgide | σzdW | MPa | 40 | 50 | 60 | 75 | 85 |

| Na-agbaji Ike | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Njupụta | g/cm3 | 7,10 | 7,15 | 7,20 | 7,25 | 7,30 | |

Ọkwa nke igwe agba ntụ ntụ nha nhata | ||||||||

| AISI | W-nkwakọba | DIN | BS | SS | AFNOR | UNE / IHA | JIS | UNI |

| A48-20B | 0,6010 | GG-10 | Nkeji 100 | 0110-00 | - | - | FC 100 | G 10 |

| A48-25B | 0.6015 | GG-15 | Nkeji 150 | 0115-00 | Ft 15 D | FG 15 | FC 150 | G 15 |

| A48-30B | 0.6020 | GG-20 | Ọkwa 200 | 0120-00 | Ft 20 D | FG 20 | FC 200 | G 20 |

| A48-40B | 0,6025 | GG-25 | Ọkwa 250 | 0125-00 | Ft 25 D | FG 25 | FC 250 | G 25 |

| A48-45B | 0,6030 | GG-30 | Ọkwa 300 | 0130-00 | Ft 30 D | FG 30 | FC 300 | G 30 |

| A48-50B | 0,6035 | GG-35 | Ọkwa 350 | 0135-00 | Ft 35 D | FG 35 | FC 350 | G 35 |

| A48-60B | 0,6040 | GG-40 | Ọkwa 400 | 0140-00 | Ft 40 D | - | FC 40 | - |

| 32510 | GTS-35 | B340/12 | 0815-00 | MN 35-10 | - | FCMW 330 | - | |

| A220-40010 | 0,8145 | GTS-45 | P440/7 | 0852-00 | MN 450 | - | FCMP 440/490 | GMN 45 |

| A220-50005 | 0,8155 | GTS-55-04 | P510/4 | 0854-00 | MP 50-5 | - | FCMP 490 | GMN 55 |

| A220-70003 | 0,8165 | GTS-65-02 | P570/3 | 0856-00 | MN 650-3 | - | FCMP 590 | GMN 65 |

| A220-70003 | - | GTS-65 | P570/3 | 0858 | MN 60-3 | - | FCMP 540 | - |

| A220-80002 | 0,8170 | GTS-70-02 | P690/2 | 0862-00 | MN 700-2 | - | FCMP 690 | GMN 70 |

Metal na Alloys nke nwere mkpuchi mkpuchi mkpuchi | |

| Ọla & Alloys | Ọkwa ewu ewu |

| Igwe ntụ ntụ ntụ | GG10~GG40; GJL-100 ~ GJL-350; |

| Ihe nkedo nke Ductile (Nodular). | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Ígwè akpata oyi akwa (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Carbon ígwè | C20, C25, C30, C45 |

| Alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Igwe anaghị agba nchara | Ferritic igwe anaghị agba nchara, Martensitic igwe anaghị agba nchara, Austenitic igwe anaghị agba nchara, ọdịda mmiri ike igwe anaghị agba nchara, Duplex igwe anaghị agba nchara. |

| Aluminom Alloys | ASTM A356, ASTM A413, ASTM A360 |

| Alloys dabere na Brass / ọla kọpa | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Ọkọlọtọ: ASTM, SAE, AISI, GOST, DIN, EN, ISO, na GB | |

Ngwaahịa nkedo ígwè omenala