Ferritic igwe anaghị agba nchara na-ezo aka igwe anaghị agba nchara nwere cubic ferrite nke dabere na ahụ dị ka usoro matriks n'ogo dị elu yana okpomoku nkịtị. Ferritic igwe anaghị agba nchara nwere ígwè na chromium dị ka ndị isi ihe, n'ozuzu anaghị enwe nickel, na ụfọdụ nwere obere ego nke molybdenum, titanium ma ọ bụ niobium na ihe ndị ọzọ. Ọ nwere ezigbo nguzogide oxidation, nguzogide corrosion na chloride corrosion cracking resistance. Na mgbakwunye, igwe anaghị agba nchara ferritic nwekwara njiri mara nnukwu ikuku ọkụ, obere ọnụọgụ mgbasawanye, ezigbo nguzogide oxidation, yana ezigbo nguzogide corrosion nrụgide. A na-ejikarị emepụta akụkụ ndị na-eguzogide ikuku, ikuku mmiri, mmiri, na oxidative acid corrosion. Ndị nnọchi anya akara ule ferritic igwe anaghị agba nchara bụ: AISI 410 (UNS S41000), AISI 420 (UNS S42000), AISI 430 (UNS S43000) dị ka ASTM; 1.4006, 1.4021, 1.4016, dị ka EN ọkọlọtọ ... wdg.

Enwere ike kewaa igwe anaghị agba nchara Ferritic ka ọ bụrụ chromium dị ala, chromium ọkara na chromium dị elu dịka ọdịnaya chromium siri dị. Dị ka ịdị ọcha nke ígwè ahụ si dị, karịsịa ọdịnaya nke carbon na nitrogen adịghị ọcha, enwere ike kewaa ya n'ime igwe anaghị agba nchara ferritic na ultra-dị ọcha ferritic igwe anaghị agba nchara. Igwe anaghị agba nchara ferritic nkịtị nwere ọghọm dị n'obere okpomoku na nhịkọ n'ime ụlọ, uche mara mma, ọdịdị corrosion intergranular dị elu, yana weldability adịghị mma. Ọ bụ ezie na e mepụtara ụdị ígwè a n'oge gara aga, a machibidoro ọrụ mmepụta ihe ya nke ukwuu. Ndị a erughi nke nkịtị ferritic igwe anaghị agba nchara metụtara ịdị ọcha nke ígwè, karịsịa ọdịnaya dị elu nke interstitial ihe dị ka carbon na nitrogen na ígwè. Ọ bụrụhaala na carbon na nitrogen dị na nchara dị ntakịrị, enwere ike imeri adịghị ike ndị dị n'elu.

Tụnyereaustenitic igwe anaghị agba nchara, ferritic igwe anaghị agba nchara nwere mma corrosion eguzogide, okpomọkụ na-eguzogide na processability. Ebe ọ bụ na oge ferrite enweghị ike igbari carbon, ferrite nwere njirimara nke ịdị nro na ịdị mfe nrụrụ. Dị ka martensitic igwe anaghị agba nchara, ebe ọ bụ na lattice Ọdịdị bụ a ahu na-adabere cubic Ọdịdị, ọ bụ paramagnetic, ya mere ferritic igwe anaghị agba nchara bụ magnetik. Igwe anaghị agba nchara Austenitic abụghị ihe ndọta n'ihi nhazi cubic nke gbadoro ụkwụ na ya.

Ọnụahịa nke igwe anaghị agba nchara ferritic abụghị naanị dị ala ma kwụsie ike, kamakwa ọ nwere ọtụtụ atụmatụ na uru pụrụ iche. E gosiputara na igwe anaghị agba nchara ferritic bụ ihe ọzọ dị oke mma.

Ferritic igwe anaghị agba nchara nkịtị

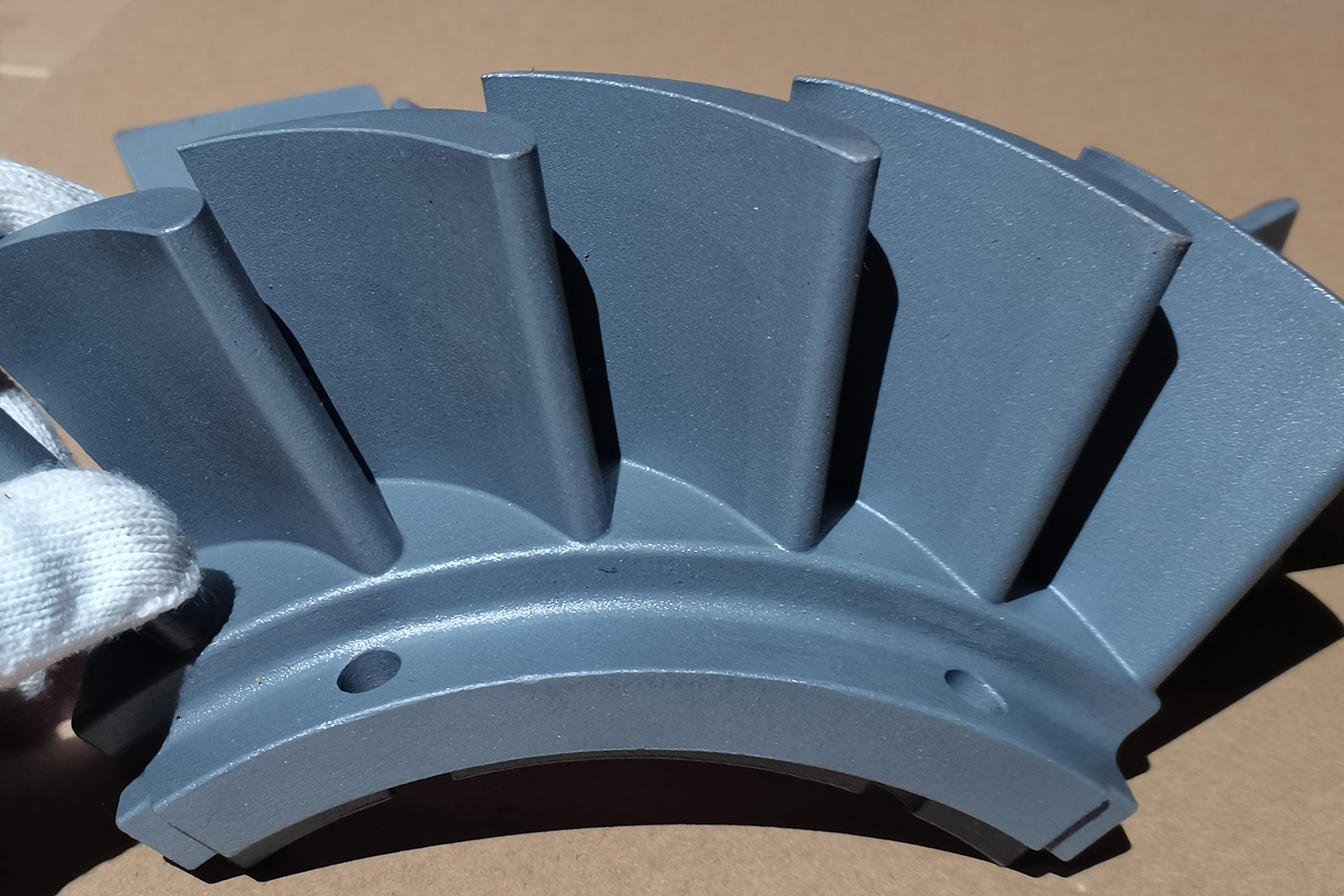

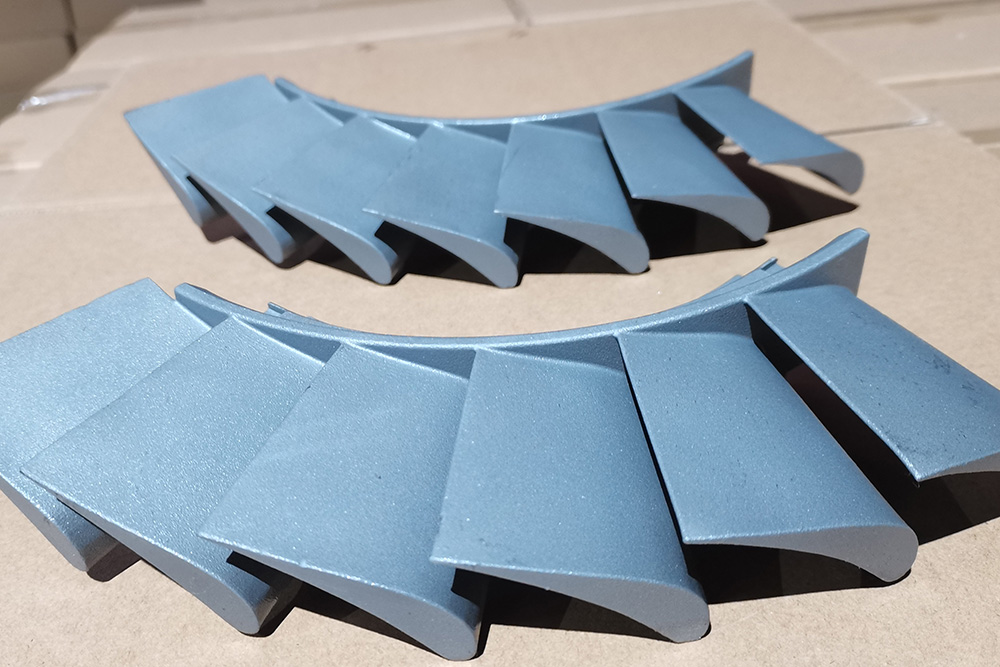

Nchara ndị dị otú ahụ na-agụnye ọdịnaya chromium dị ala, ọkara na elu. Igwe anaghị agba nchara chromium ferritic dị ala nwere ihe dịka 11% ruo 14% chromium, dị ka 00Cr12 na 0Cr13Al na China. American AISI 400, 405, 406MF-2. Ụdị ígwè a nwere ezigbo ike, plasticity, oyi nrụrụ na weldability. N'ihi na ígwè nwere ụfọdụ chromium na aluminom, ọ nwere ezigbo nguzogide oxidation na nchara nchara. 405 nwere ike ji mee ihe dị ka mmanụ ụgbọala refining ụlọ elu, tank lining, uzuoku turbine agụba, elu okpomọkụ sọlfọ corrosion eguzogide ngwaọrụ, wdg 400 maka ezinụlọ na ụlọ ọrụ ngwa, wdg 409 na-eji maka ụgbọala iyuzucha muffler usoro ngwaọrụ na oyi na-ekpo ọkụ na mmiri ọkpọkọ. wdg. Ọkara chromium ferritic igwe anaghị agba nchara, ọdịnaya chromium bụ 14% ruo 19%, dị ka 1Cr17 na 1Cr17Mo na China. AISI 429, AISI 430, AISI 433, AISI 434, AISI 435, AISI 436, AISI 439 na United States. Ụdị nchara a ka mma nchara na nguzogide corrosion. Ọnụ ọgụgụ ya na-arụsi ọrụ ike dị obere (n≈2), yana ọ nwere arụmọrụ dị omimi miri emi, mana ductility ya adịghị mma. A na-eji AISI 430 ferritic igwe anaghị agba nchara maka ihe ndozi ụlọ, ihe ịchọ mma ụgbọ ala, akụrụngwa kichin, ndị na-ere ọkụ gas na akụkụ nke akụrụngwa ụlọ ọrụ nitric acid, wdg. A na-eji AISI 434 mee ihe ịchọ mma mpụga nke ụgbọ ala na ụlọ. A na-eji 439 dị ka eriri maka ndị na-ekpo ọkụ gas, coal na gas pipeline, wdg High chromium ferritic igwe anaghị agba nchara nwere 19% ruo 30% chromium, dị ka Cr18Si2 na Cr25 na China, AISI 442, AISI 443 na AISI 446 na United States. Steeti. Ụdị ígwè ndị dị otú ahụ nwere ezigbo nguzogide oxidation. A na-eji AISI 442 na-aga n'ihu na ikuku, oke okpomọkụ dị elu bụ 1035 ° C, na okpomọkụ kachasị maka iji ya na-aga n'ihu bụ 980 ° C. AISI 446 ferritic igwe anaghị agba nchara nwere mma oxidation nguzogide.

Igwe anaghị agba nchara ferritic dị oke ọchal

Ụdị ígwè a nwere obere carbon, nitrogen; elu chromium, molybdenum, titanium, niobium na ihe ndị ọzọ. Dị ka China 00Cr17Mo, 00Cr18Mo2, 00Cr26Mol, 00Cr30Mo2. Ụdị nchara a nwere ezigbo ihe eji arụ ọrụ (karịsịa ike siri ike), weldability, intergranular corrosion resistance, pitting corrosion resistance, crevice corrosion resistance, and the great stress corrosion cracking resistance. Dịka ọmụmaatụ, 18-2 ferritic igwe anaghị agba nchara nwere ezigbo nguzogide corrosion na nitric acid, acetic acid, NaOH, pitting corrosion resistance na 3% NaCl na FeCl3 bụ otu ma ọ bụ karịa 18-8 austenitic igwe anaghị agba nchara, 26CrMo ígwè n'ọtụtụ mgbasa ozi nguzogide corrosion. , karịsịa na organic acids, oxidizing acids, na ike alkalis. Ọ nwere nguzogide corrosion dị mma na chloride siri ike. Enweghị mgbawa corrosion nrụgide na-eme na chloride, hydrogen sulfide, sulfuric acid gabigara ókè na alkali siri ike. 30Cr-2Mo nwere nguzogide dị elu maka ikpochapụ corrosion na crevice corrosion ka ọ na-ejigide nguzogide corrosion nrụgide.

Nguzogide corrosion nke igwe anaghị agba nchara ferritic

(1) Uwe oyibo corrosion.

Chromium bụ ihe kachasị mfe ịmefefe. Na gburugburu ikuku, ígwè-chromium alloy nwere chromium ọdịnaya nke ihe karịrị 12% nwere ike ịpụ onwe ya. Na usoro oxidizing, ọdịnaya chromium nwere ike ịfefe ma ọ bụrụ na ọ karịrị 17%. N'ihe ụfọdụ na-emebi emebi, enwere ike ịgbakwunye chromium dị elu na molybdenum, nickel, ọla kọpa na ihe ndị ọzọ iji nweta ezigbo nguzogide corrosion.

(2) corrosion intergranular.

Ferritic igwe anaghị agba nchara, dị ka austenitic igwe anaghị agba nchara, na-ata ahụhụ site intergranular corrosion, ma mmetụta uche ọgwụgwọ na okpomọkụ ọgwụgwọ iji zere a corrosion bụ nnọọ iche. Ferritic igwe anaghị agba nchara dị mfe na intergranular corrosion si ngwa ngwa jụrụ n'elu 925 ° C, na steeti (nnọọ mmetụta) nke nwere ike ime ka intergranular corrosion nwere ike kpochapụ mgbe obere oge nke tempering na 650-815 ° C. Nchikota nke intergranular nke ígwè ferritic bụkwa ihe si na mbelata chromium kpatara site na mmiri ozuzo carbide. Ya mere, ibelata ọdịnaya nke carbon na nitrogen na ígwè na ịgbakwunye ihe ndị dị ka titanium na niobium nwere ike ibelata ihe mgbochi na corrosion intergranular.

(3) nrụrụ aka na nrụrụ aka.

Chromium na molybdenum bụ ihe kachasị dị irè iji kwalite nguzogide corrosion nke igwe anaghị agba nchara. Ka ọdịnaya chromium na-abawanye, ọdịnaya chromium na fim oxide na-abawanye, na nkwụsi ike kemịkalụ nke ihe nkiri ahụ na-abawanye. A na-etinye molybdenum n'elu igwe na-arụ ọrụ n'ụdị MoO4, nke na-egbochi mgbasa nke ígwè ahụ, na-akwalite mmeghari, na-egbochi mmebi nke ihe nkiri ahụ. Ya mere, elu chromium na molybdenum ferritic igwe anaghị agba nchara nwere magburu onwe iguzogide pitting na crevice corrosion.

(4) Nguzogide nrụgide corrosion cracking.

N'ihi njirimara nke nhazi nhazi, ferritic igwe anaghị agba nchara na-eguzogide corrosion na ọkara ebe austenitic igwe anaghị agba nchara na-emepụta nrụgide corrosion cracking.

Njirimara igwe nke igwe anaghị agba nchara ferritic

Ferritic igwe anaghị agba nchara enweghị ike iwusi ya ike site na ọgwụgwọ okpomọkụ n'ihi na ọ nweghị mgbanwe oge. N'ozuzu, a na-eji ya mgbe annealing na 700-800 ° C. N'ihi nha atomic yiri nke ígwè na chromium, mmetụta siri ike na-eme ka ihe ngwọta siri ike dị ntakịrị, ike mkpụrụ na ike ike nke ferritic igwe anaghị agba nchara dị elu karịa nke obere carbon ígwè, na ductility dị ala karịa nke obere carbon ígwè. .

1) Ime ụlọ okpomọkụ brittleness nke nkịtị ferritic igwe anaghị agba nchara.

Igwe anaghị agba nchara ferritic nkịtị na-enwe mmetụta maka ọkwa ọkwa, na mgbanwe mgbanwe okpomọkụ dị n'elu ọnụ ụlọ ma e wezụga maka igwe anaghị agba nchara chromium ferritic dị ala. Ka ọdịnaya chromium dị elu, otú ahụ ka ọ na-agbaji oyi. Ọkpụkpọ oyi a na-ejikọta ya na ihe ndị dị n'etiti dị ka carbon na nitrogen dị na ígwè, na ultra-dị ọcha ferritic ígwè nwere nnukwu carbon ọdịnaya dị na interstitial ọcha dị ka carbon na nitrogen, n'ihi ya, ọ nwere ike nweta ezigbo ike siri ike, na nchikota mgbanwe. enwere ike iweda ọnọdụ okpomọkụ n'okpuru ụlọ okpomọkụ.

2) High okpomọkụ embrittlement nke nkịtị ferritic igwe anaghị agba nchara.

Igwe anaghị agba nchara ferritic nkịtị na-ekpo ọkụ ka ọ dị elu karịa 927 ° C wee mee ka ọ dị jụụ ngwa ngwa n'ime ụlọ, plasticity na ike na-ebelata nke ukwuu. Ọkpụkpọ a na-ekpo ọkụ dị elu jikọtara ya na mmiri ozuzo ngwa ngwa nke ogige carbon (nitride) na oke ọka ma ọ bụ nkwụsịtụ na okpomọkụ nke 427-927 °C. Mbelata carbon na nitrogen ọdịnaya nke ígwè (iji ultra-ọcha teknụzụ) nwere ike imeziwanye nhịkọ a. Tụkwasị na nke ahụ, mgbe ígwè ferritic na-ekpo ọkụ n'elu 927 ° C, a ga-eme ka ikike nke ọka kpụọ, na ọka na-adịghị ahụkebe ga-emebi plasticity na ike nke ígwè ahụ.

3) Nhazi nke σ-phase.

Dabere na eserese oge nke iron-chromium, mgbe edobere ya na 500-800 Celsius, alloy nwere 40%-50% chromium ga-etolite otu akụkụ σ, na alloy nwere ihe na-erughị 20% ma ọ bụ karịa 70% chromium ga-etolite. nhazi α+σ dual-phase. Nhazi nke σ-phase ga-ebelata ductility na siri ike nke ígwè. Ya mere, igwe anaghị agba nchara ferritic ekwesịghị iji ogologo oge na 500-800 Celsius.

4) Ọkụkụ na 475°C.

Igwe chromium dị elu (> 15%) ferritic steel ga-agbakọ nke ọma mgbe edobere ya na 400-500 Celsius. Ụdị embrittlement a na-ewe oge dị mkpirikpi karịa mmiri ozuzo nke oge σ. Dịka ọmụmaatụ, mgbe 0.080C-0.4Si-16.9Cr ferritic igwe anaghị agba nchara na-edobe na 450ºC maka awa 4, ọnọdụ okpomọkụ nke ime ụlọ na-enwe mmetụta siri ike fọrọ nke nta ka ọ daa na efu. Ogo nke mgbakasị ahụ na-abawanye site na mmụba nke ọdịnaya chromium, mana ike ahụ nwere ike nwetaghachi mgbe ọgwụgwọ karịrị 600 Celsius. Embrittlement na 475°C bụ ihe si na mmiri ozuzo nke chromium-ọgaranya alfa. Igwe dị otú ahụ kwesịrị izere ikpo ọkụ na nso 475 Celsius.

Oge nzipu: Mee-02-2023