Nkedo ígwè na-eguzogide iyi (ma ọ bụ abrasion na-eguzogide) na-ezo aka nchara nkedo nwere ezigbo nguzogide eyi. Dị ka ihe mejupụtara kemịkalụ si dị, a na-ekewa ya n'ime nchara na-abụghị alloy, alloy alloy na alloy wear-eguzogide ígwè. Enwere ọtụtụ ụdị nchara na-eguzogide, nke enwere ike kewaa n'ime nchara dị elu, ọkara na obere alloy wear-eguzogide ígwè, chromium-molybdenum-silicon-manganese ígwè, cavitation-eguzogide ígwè, eyi na-eguzogide ígwè. na ígwè pụrụ iche na-eguzogide eyi. A na-ejikwa ụfọdụ nchara alloy n'ozuzu dịka igwe anaghị agba nchara, igwe na-ebu ígwè, ihe eji arụ ọrụ alloy na alloy structural steel a na-ejikwa dị ka nchara na-eguzogide oyi n'okpuru ọnọdụ ụfọdụ.

Ọkara na obere alloy na-eguzogide nchara na-enwekarị ihe kemịkal dị ka silicon, manganese, chromium, molybdenum, vanadium, tungsten, nickel, titanium, boron, ọla kọpa, ala ndị na-adịghị ahụkebe, wdg. The liners nke ọtụtụ nnukwu na ọkara-sized bọọlụ. igwe igwe na United States bụ nke chromium-molybdenum-silico-manganese ma ọ bụ chromium-molybdenum ígwè. Ihe ka ọtụtụ n'ime bọọlụ egweri na United States bụ nke ọkara na nnukwu carbon chromium molybdenum ígwè. N'ihi na workpieces na-arụ ọrụ n'okpuru dịtụ elu okpomọkụ (dịka ọmụmaatụ, 200 ~ 500 ℃) abrasive eyi ọnọdụ ma ọ bụ ndị elu na-edobere dịtụ elu okpomọkụ n'ihi frictional okpomọkụ, alloys dị ka chromium molybdenum vanadium, chromium molybdenum vanadium nickel ma ọ bụ chromium molybdenum vanadium tung. enwere ike iji.

Abrasion bụ ihe na-eme ka ihe dị n'elu ihe na-arụ ọrụ na-emebi ma ọ bụ na-efunahụ ya na mmegharị. N'ịbụ ndị e kewara site na usoro ejiji, ejiji nwere ike kewaa n'ime abrasive wear, nrapado wear, corrosion wear, erosion wear, contact wear wear, impact wear, fretting wear and other edemede. Na ulo oru ubi, abrasive eyi na nrapado wear akaụntụ maka kasị ukwuu nkezi nke workpiece eyi ọdịda, na-eyi ọdịda ụdịdị dị ka ozize, corrosion, ike ọgwụgwụ, na fretting na-emekarị na-eme na ọrụ nke ụfọdụ ihe dị mkpa components, n'ihi ya, ha na-enweta ihe ndị ọzọ. na nlebara anya ọzọ. N'okpuru ọnọdụ ọrụ, ọtụtụ ụdị ejiji na-apụtakarị n'otu oge ma ọ bụ otu mgbe ọzọ, na mmekọrịta nke ọdịda ọdịda na-ewere ọnọdụ dị mgbagwoju anya. Ịchọpụta ụdị ọdịda ọdịda nke workpiece bụ ihe ndabere maka nhọrọ ezi uche dị na ya ma ọ bụ mmepe nke nchara na-eguzogide.

Na mgbakwunye, iyi nke akụkụ na akụrụngwa bụ nsogbu injinia sistemu. Enwere ọtụtụ ihe na-emetụta uwe, gụnyere ọnọdụ ọrụ (ibu, ọsọ, ọnọdụ mmegharị), ọnọdụ mmanu mmanu, ihe gburugburu ebe obibi ( iru mmiri, okpomọkụ, mgbasa ozi gbara ya gburugburu, wdg), na ihe onwunwe (Ihe mejupụtara, nhazi, ihe eji arụ ọrụ), elu. àgwà na anụ ahụ na chemical Njirimara nke akụkụ. Mgbanwe na nke ọ bụla n'ime ihe ndị a nwere ike gbanwee ọnụ ọgụgụ nke uwe na ọbụna gbanwee usoro ejiji. Enwere ike ịhụ na ihe eji eme ihe bụ naanị otu n'ime ihe ndị na-emetụta uwe nke workpiece. Iji meziwanye ihe mgbochi nke akụkụ ígwè, ọ dị mkpa ịmalite site na esemokwu zuru oke na usoro ejiji n'okpuru ọnọdụ ụfọdụ iji nweta mmetụta a chọrọ.

1. Ngwọta Okpomọkụ Ngwọta (Ọgwụgwọ na-eme ka mmiri sie ike) nke ihe nkedo ígwè dị elu nke Manganese na-eguzogide oyi.

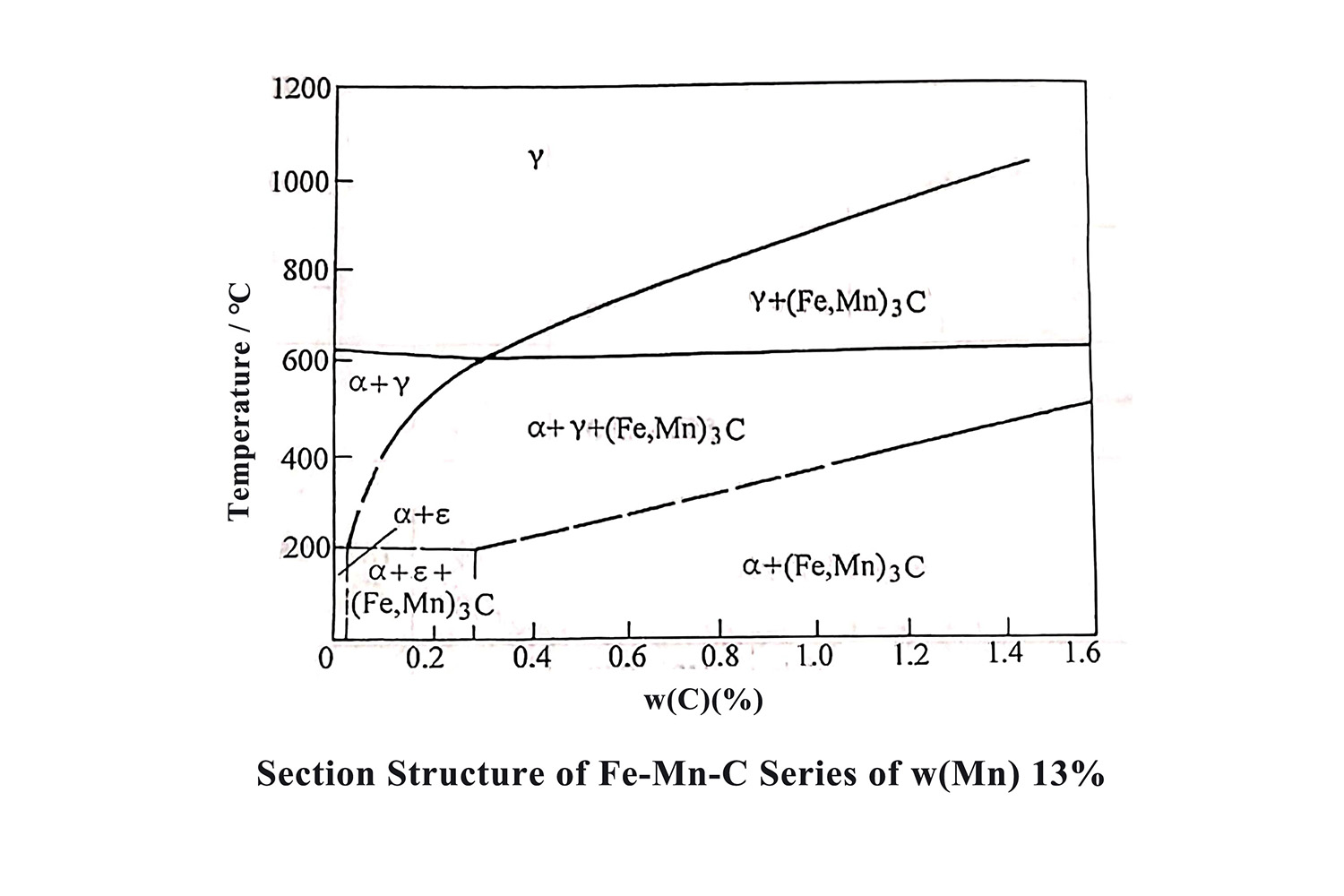

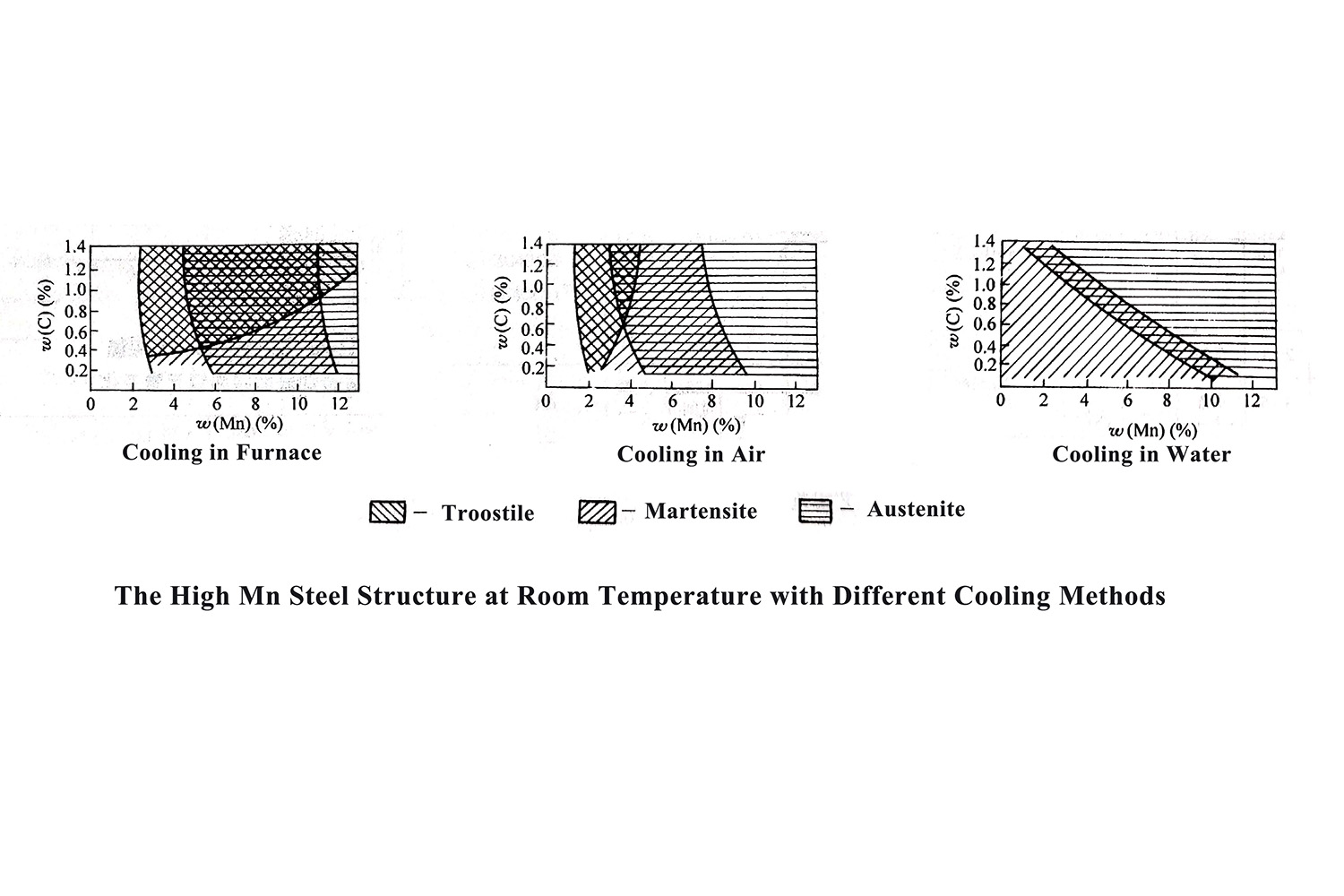

Enwere ọnụ ọgụgụ buru ibu nke carbide a na-agbapụta agbawa na nhazi nkedo nke igwe na-eyi akwa manganese dị elu. Ndị a carbides ga-ebelata ike nke nkedo ma mee ka ọ dị mfe mgbaji n'oge eji. Ebumnuche bụ isi nke ngwọta okpomọkụ ọgwụgwọ nke nnukwu manganese ígwè nkedo bụ ikpochapụ carbides dị ka nkedo Ọdịdị na na ọka ókè-ala iji nweta otu-phase austenite Ọdịdị. Nke a nwere ike imeziwanye ike na isi ike nke nnukwu ígwè manganese, nke mere na nnukwu ihe nkedo manganese dị mma maka ọtụtụ ubi.

Enwere ike kewaa ihe ngwọta okpomọkụ nke ihe nkedo ígwè dị elu manganese na-eguzogide n'ụzọ dị iche iche: kpoo ihe nkedo ahụ ruo n'elu 1040 Celsius C ma jide ya maka oge kwesịrị ekwesị, nke mere na carbides n'ime ya na-agbaze kpamkpam na otu oge austenite. ; mgbe ahụ ngwa ngwa jụrụ , Nweta austenite siri ike ngwọta Ọdịdị. A na-akpọkwa ọgwụgwọ ngwọta a ọgwụgwọ mmiri siri ike.

(1) Okpomọkụ ọgwụgwọ na-eme ka mmiri sie ike

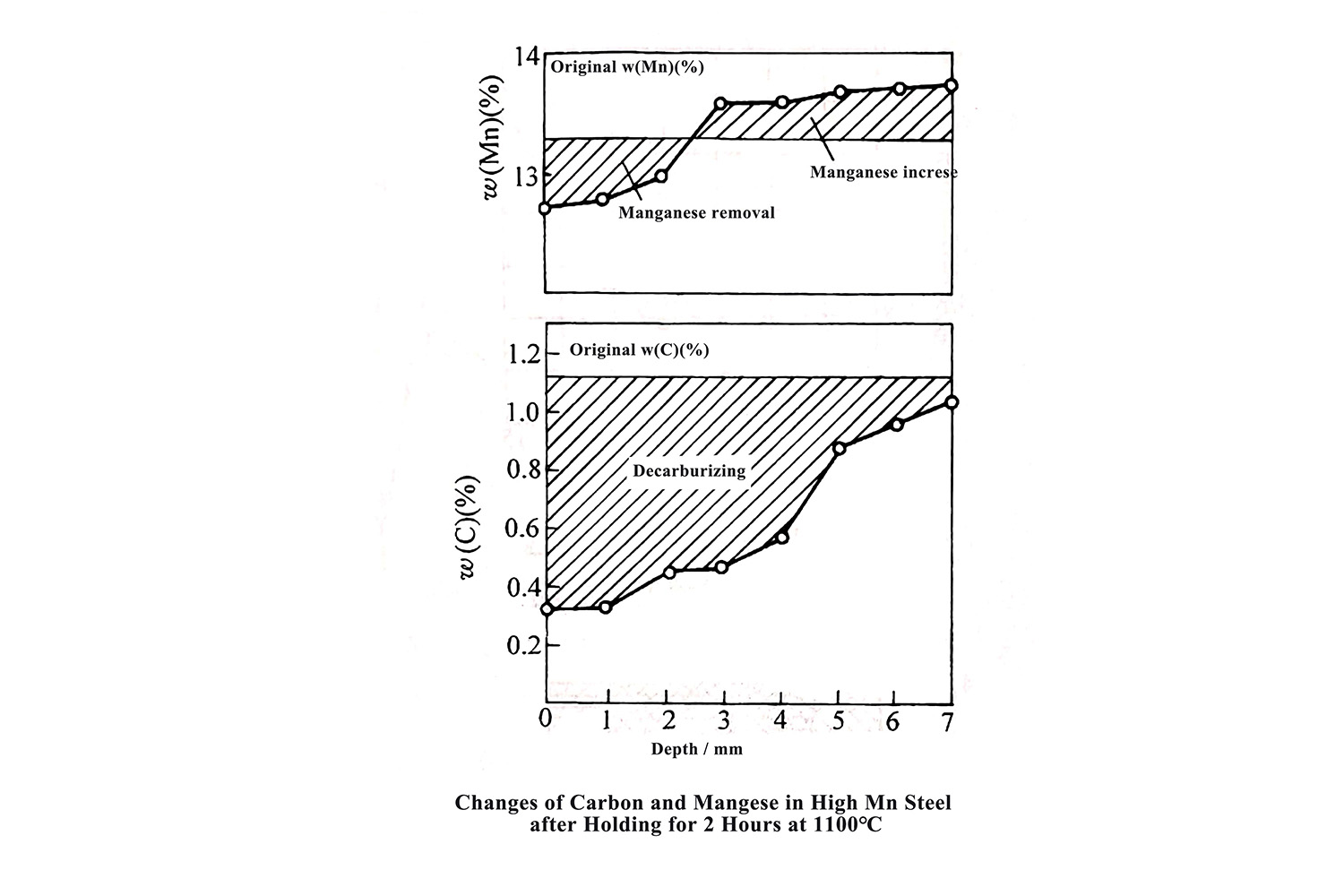

Mmiri siri ike okpomọkụ na-adabere na chemical mejupụtara nke elu manganese ígwè, na-emekarị 1050 ℃-1100 ℃. Ngwongwo manganese dị elu nwere ọdịnaya carbon dị elu ma ọ bụ ọdịnaya alloy dị elu (dịka ZG120Mn13Cr2 steel na ZG120Mn17 steel) kwesịrị iburu oke elu nke mmiri siri ike. Otú ọ dị, oke okpomọkụ dị elu nke mmiri siri ike ga-eme ka ọkpụkpụ siri ike dị n'elu nkedo ahụ na ngwa ngwa ngwa ngwa nke nnukwu ígwè manganese, nke ga-emetụta arụmọrụ nke ígwè manganese dị elu.

(2) Ọnụego ikpo ọkụ nke ọgwụgwọ na-eme ka mmiri sie ike

The thermal conductivity nke manganese ígwè dị njọ karịa nke izugbe carbon ígwè. Ihe nkedo ígwè dị elu nke manganese nwere nrụgide dị elu ma dị mfe ịgbawa mgbe a na-ekpo ọkụ, n'ihi ya, a ga-ekpebi ọnụego ọkụ dị ka mgbidi mgbidi na ọdịdị nke nkedo ahụ si dị. N'ikwu okwu n'ozuzu, ihe nkedo nwere obere mgbidi na nhazi dị mfe nwere ike ikpo ọkụ na ọsọ ọsọ; ihe nkedo nwere ọkpụrụkpụ mgbidi buru ibu na ihe dị mgbagwoju anya kwesịrị iji nwayọ kpoo ọkụ. N'ime usoro ọgwụgwọ okpomọkụ n'ezie, iji belata nrụrụ ma ọ bụ mgbawa nke nkedo n'oge usoro ikpo ọkụ, a na-ekpo ọkụ n'ozuzu ruo ihe dịka 650 ℃ iji mee ka ọdịiche dị n'etiti ime na n'èzí nke nkedo ahụ belata, na okpomọkụ dị na ya. ọkụ bụ edo, na mgbe ahụ ngwa ngwa ebili na mmiri ike okpomọkụ.

(3) Idebe oge ọgwụgwọ na-eme ka mmiri sie ike

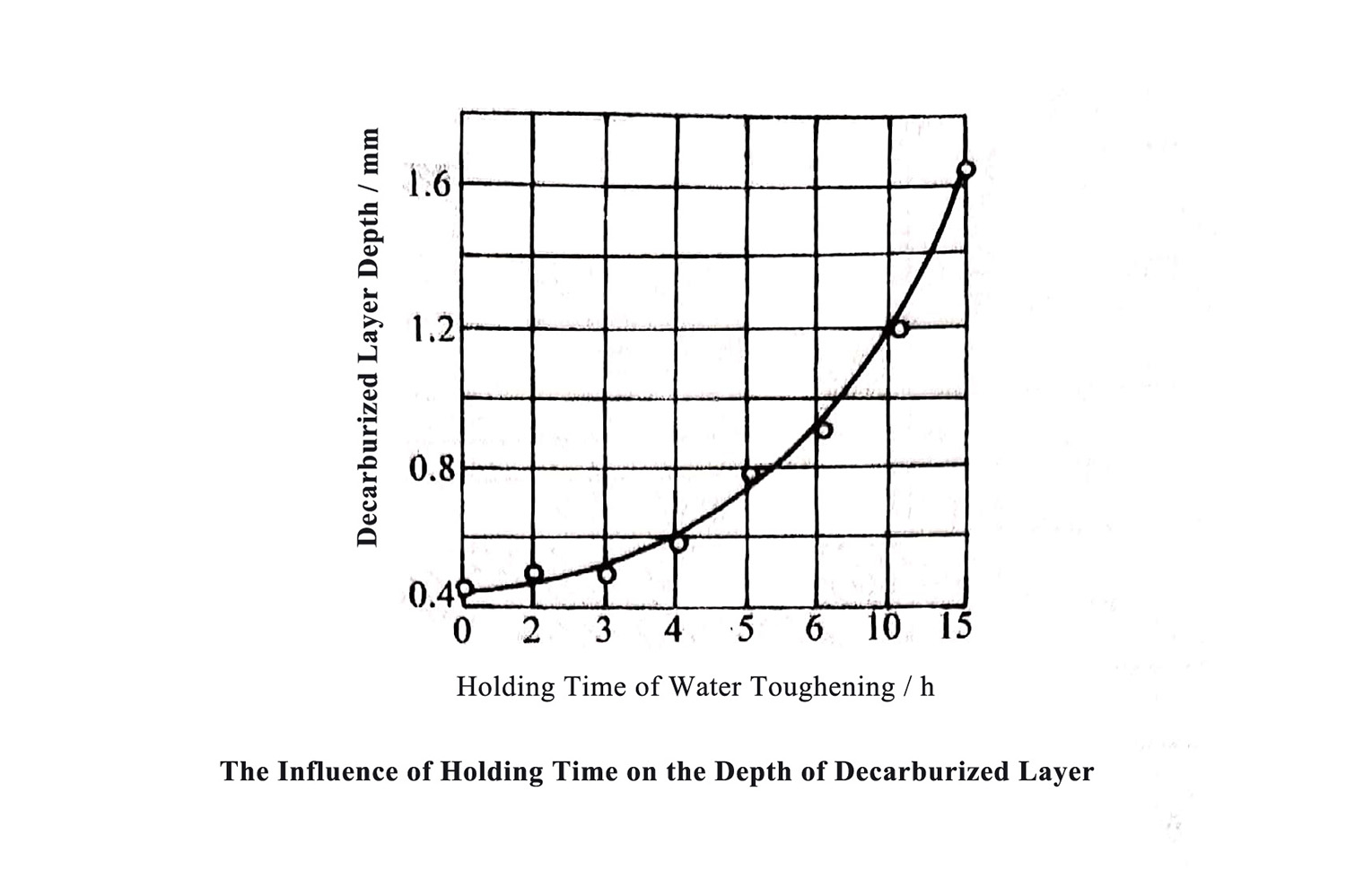

Njide oge nke mmiri toughening ọgwụgwọ tumadi na-adabere na mgbidi ọkpụrụkpụ nke nkedo, iji hụ na mgbasa zuru ezu nke carbides dị ka-nkedo Ọdịdị na homogenization nke austenite Ọdịdị. N'okpuru ọnọdụ nkịtị, enwere ike ịgbakọ ya site na ịbawanye oge njide site na 1 awa maka mmụba 25 mm ọ bụla na ọkpụrụkpụ mgbidi.

(4) Ịjụ ọgwụgwọ na-eme ka mmiri sie ike

Usoro jụrụ oyi na-enwe mmetụta dị ukwuu na ntinye aka na nhazi nke nkedo. N'oge ọgwụgwọ mmiri siri ike, okpomọkụ nke nkedo tupu ịbanye na mmiri kwesịrị ịdị n'elu 950 ° C iji gbochie carbides ịmaliteghachi. N'ihi nke a, oge etiti oge n'etiti ịwụpụ n'ọkụ na ịbanye na mmiri ekwesịghị gafere 30 sekọnd. Okpomọkụ mmiri kwesịrị ịdị n'okpuru 30 Celsius C tupu nkedo abanye na mmiri, na oke mmiri mmiri mgbe ị banyere na mmiri ekwesịghị gafere 50 Celsius.

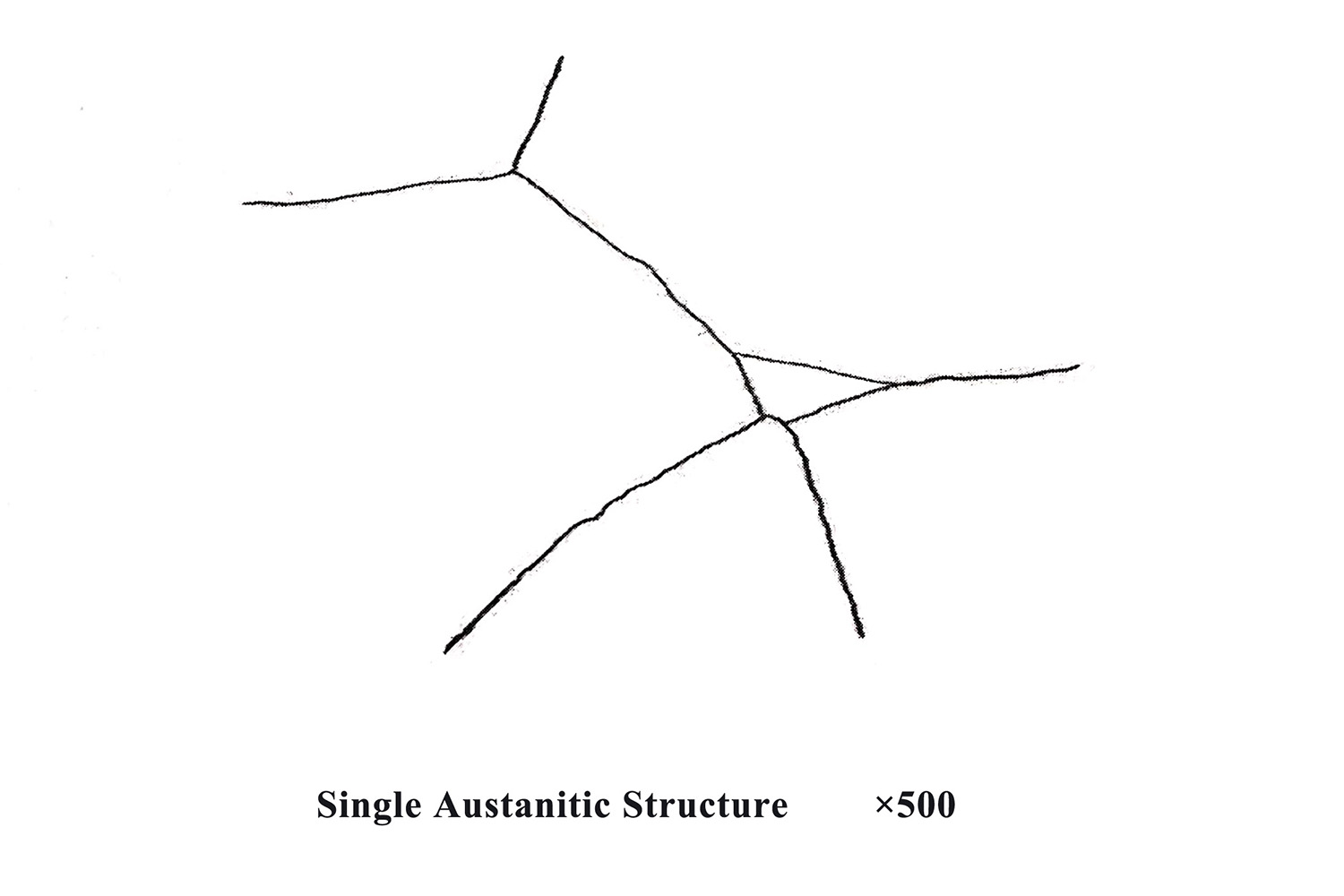

(5) Carbide mgbe mmiri toughening ọgwụgwọ

Mgbe ọgwụgwọ na-eme ka mmiri sie ike, ọ bụrụ na a na-ekpochapụ carbides na ígwè manganese dị elu kpamkpam, usoro metallographic nwetara n'oge a bụ otu ihe owuwu austenite. Ma ụdị ihe owuwu dị otú ahụ nwere ike nweta naanị na nkedo nwere obere mgbidi. N'ozuzu, a na-ahapụ obere obere carbide na ọka austenite ma ọ bụ na oke ọka. Enwere ike ikpochapụ carbide na-agbasaghị na carbide na-ebuli elu site na ọgwụgwọ okpomọkụ ọzọ. Agbanyeghị, eutectic carbides na-ebuli n'ihi oke okpomoku okpomoku n'oge ọgwụgwọ mmiri siri ike adịghị anabata. N'ihi na enweghi ike ikpochapụ eutectic carbide site na ọgwụgwọ okpomọkụ ọzọ.

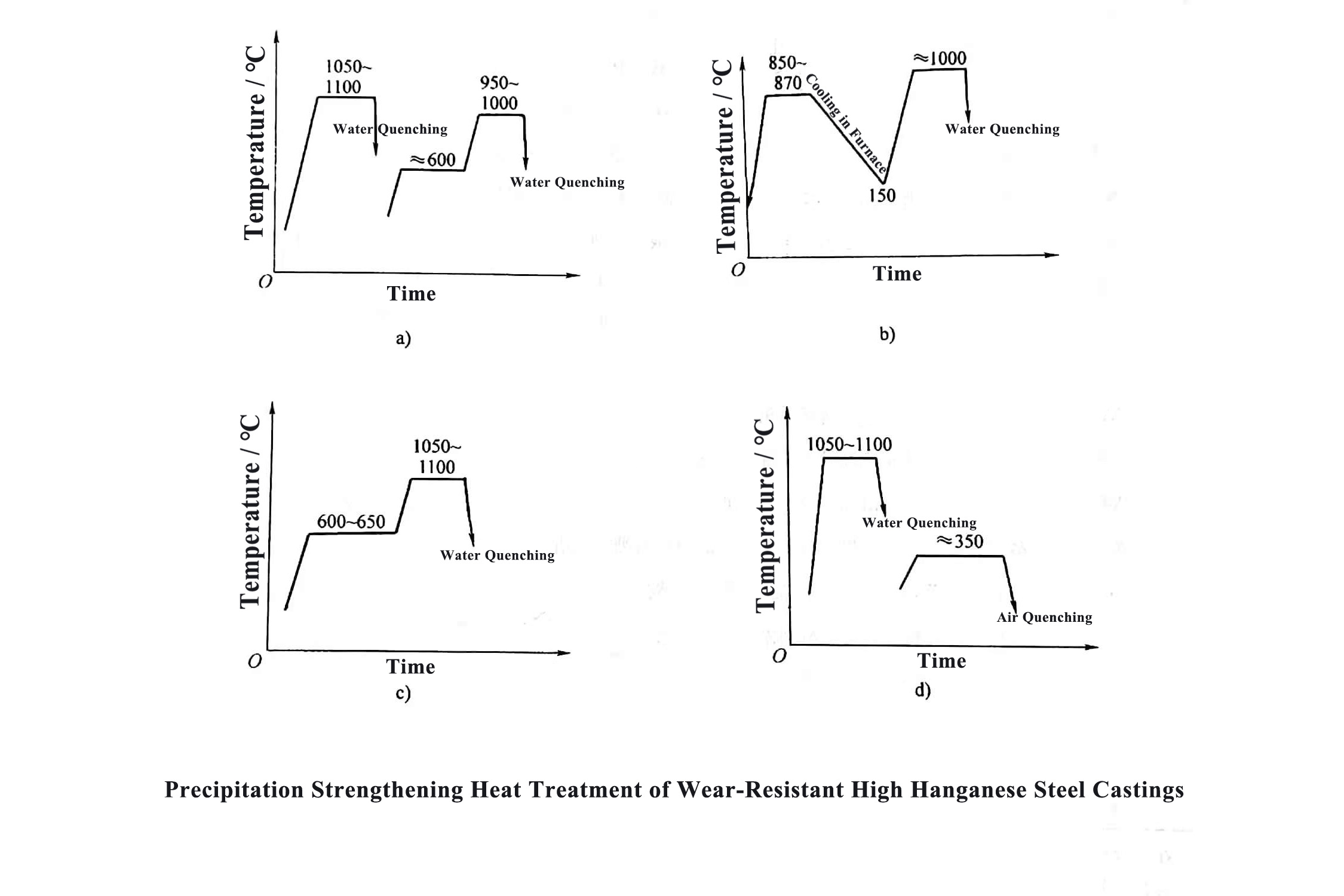

2. Ọdịda Anyanwụ na-eme ka ọ dị ike ọgwụgwọ okpomọkụ nke ihe nkedo ígwè Hanganese dị elu na-eguzogide eyi.

Mmiri ozuzo na-eme ka okpomọkụ dị elu nke ígwè manganese dị elu na-eguzogide na-ezo aka na mgbakwunye nke ụfọdụ ego nke carbide na-emepụta ihe (dị ka molybdenum, tungsten, vanadium, titanium, niobium na chromium) site na ọgwụgwọ okpomọkụ iji nweta ụfọdụ ego na nha. elu manganese ígwè Nkeji nke abụọ nke achụsasị carbide ahụ. Ọgwụgwọ okpomọkụ a nwere ike ime ka matrix austenite sie ike ma melite nguzogide eyi nke nnukwu manganese ígwè.

3. Ọgwụgwọ okpomọkụ nke ihe nkedo Chromium Steel Ọkara na-eguzogide eyi

Ebumnuche nke ọgwụgwọ okpomọkụ nke ihe nkedo chromium ígwè na-eguzogide na-eyi bụ iji nweta ihe nrụpụta matriks nke martensite nwere ike dị elu, ike siri ike na ịdị elu dị elu, iji mee ka ike dịkwuo mma, ike na iyi nkwụsị nke nkedo ígwè.

Ọkpụkpụ chromium na-eguzogide iyi nwere ihe ndị ọzọ chromium ma nwee ike siri ike dị elu. Ya mere, ya na-emebu okpomọkụ ọgwụgwọ usoro bụ: mgbe 950 ℃-1000 ℃, ya austenitization, mgbe ahụ quenching ọgwụgwọ, na-adọ tempering ọgwụgwọ (na-emekarị na 200-300 ℃).

4. Ọgwụgwọ okpomọkụ nke nkedo ígwè dị ala na-eguzogide oyi

A na-emeso ihe nkedo nchara dị ala na-eguzogide ọgwụ site n'imenyụ mmiri, na-emenyụ mmanụ na ikuku ikuku dabere na ihe mejupụtara alloy na ọdịnaya carbon. Ihe nkedo na-eyi pelịtic na-anabata ọgwụgwọ ikpo ọkụ + na-ekpo ọkụ.

Iji nweta matriks martensite nke nwere ike dị elu, ike na ike siri ike, yana iji melite nguzogide nkedo nke ígwè, ihe nkedo ígwè dị ala na-eguzogide ọgwụ na-emekarị ka ọ kwụsịchaa na 850-950 ° C ma na-ekpo ọkụ na 200-300 ° C. .

Oge nzipu: Ọgọst-07-2021