Industrial electrocoating bụ a n'ọtụtụ ebe na-eji elu ọgwụgwọ maka ichebe ndịihe nkedo ígwèna CNC machining ngwaahịa si corrosion na mma imecha. Ọtụtụ ndị ahịa na-ajụ ajụjụ gbasara ọgwụgwọ elu nke nkedo ígwè nankenke machined akụkụ. Isiokwu a ga-elekwasị anya na electrophoretic mkpuchi usoro. Enwere olileanya na ọ ga-enyere ndị mmekọ niile aka.

Electrocoating bụ usoro mkpuchi nke ihe ndị dị ka pigmenti na resins kwụsịtụrụ na ngwọta electrophoretic na-adabere na ịkwaga na nkwụnye n'elu otu n'ime electrodes site na iji ọkụ eletrik dị n'èzí. E mepụtara ụkpụrụ nke mkpuchi electrophoretic na njedebe nke 1930, ma e mepụtara nkà na ụzụ a ma nweta ngwa ụlọ ọrụ mmepụta ihe mgbe 1963. Ihe mkpuchi electrophoretic bụ usoro ihe owuwu kachasị mma maka mkpuchi mmiri. Ihe mkpuchi electrophoretic nwere njirimara nke mmiri solubility, adịghị egbu egbu, na njikwa akpaka dị mfe. N'ihi na ọ bụ adabara elu ọgwụgwọ conductive workpieces (metal nkedo, machined akụkụ, forgings, mpempe akwụkwọ metal akụkụ na ịgbado ọkụ akụkụ, wdg), na electrophoretic mkpuchi usoro ngwa ngwa e ọtụtụ-eji na ụlọ ọrụ dị ka ụgbọala, ụlọ ihe, ngwaike. , na ngwa ụlọ.

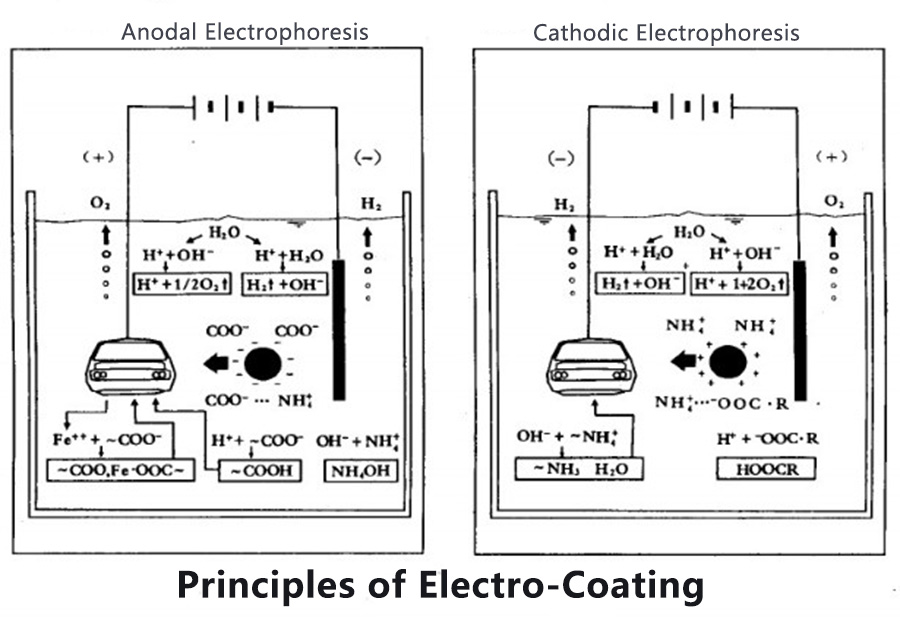

Ụkpụrụ

The resin dị na cathodic electrophoretic mkpuchi nwere isi otu, nke na-etolite a nnu mgbe acid neutralization na igbari n'ime mmiri. Mgbe etinyere ihe dị ugbu a, ion ọjọọ acid radical na-aga n'ihu na anode, na resin ion na pigmenti pigmenti nke ha na-ekpuchi na-aga na cathode na ụgwọ dị mma ma na-edebe ya na cathode. Nke a bụ ụkpụrụ bụ isi nke mkpuchi electrophoretic (nke a na-akpọkarị plating). Mkpuchi Electrophoresis bụ mmeghachi omume electrochemical dị mgbagwoju anya, ọ dịkarịa ala mmetụta anọ nke electrophoresis, electrodeposition, electrolysis, na electroosmosis na-eme n'otu oge.

Electrophoresis

Mgbe anode na cathode dị na ngwọta colloidal agbanyere, ihe ndị na-emepụta colloidal na-aga n'akụkụ cathode (ma ọ bụ anode) n'okpuru ọrụ nke ọkụ eletrik, nke a na-akpọ electrophoresis. Ihe dị na ngwọta colloidal adịghị na steeti ụmụ irighiri ihe na ion, ma solute gbasasịrị na mmiri mmiri. Ihe dị n'ime ya buru ibu ma ọ gaghị agbanye n'ime ala gbasasịrị.

Electrodeposition

Ihe omume nke mmiri ozuzo siri ike sitere na mmiri mmiri a na-akpọ agglomeration (agglomeration, deposition), nke a na-emepụtakarị mgbe ọ na-eme ka ọ dị jụụ ma ọ bụ na-etinye uche na ngwọta, na mkpuchi electrophoretic na-adabere na ọkụ eletrik. Na mkpuchi electrophoretic cathodic, ụmụ irighiri ihe ebubo nke ọma na-agbakọta na cathode, na ihe ebubo ebubo na-adịghị mma (ie ions) na-agbakọta na anode. Mgbe mma ebubo colloidal ahụ (resin na pigmenti) rute cathode (mkpụrụ osisi) Mgbe elu ebe (ukwuu alkaline interface oyi akwa), electrons na-enwetara na-emeghachi omume na hydroxide ion na-aghọ mmiri-insoluble bekee, nke na-edebe na cathode. eserese na-arụ ọrụ).

Electrolysis

Na ngwọta na ionic conductivity, anode na cathode jikọtara ya kpọmkwem ugbu a, anions na-adọta na anode, na cations na-adọta na cathode, na mmeghachi omume kemịkal na-eme. The anode na-emepụta metal dissolution na electrolytic oxidation na-emepụta oxygen, chlorine, wdg. The anode bụ electrode nke nwere ike ịmepụta oxidation mmeghachi omume. A na-agbanye ígwè ahụ na cathode na H + na-ebelata electrolytically ka ọ bụrụ hydrogen.

Electrosmosis

Mgbe njedebe abụọ ahụ (cathode na anode) nke ngwọta dị iche iche dị iche iche kewapụrụ site na akpụkpọ anụ semipermeable na-eme ka ike dị ike, ihe na-eme ka ihe ngwọta dị ala na-aga n'akụkụ dị elu nke a na-akpọ electroosmosis. Ihe nkiri mkpuchi nke a na-etinye n'elu ihe a na-ekpuchi ya bụ ihe nkiri na-eme ka ọ dị ọkara. N'okpuru ọrụ eletrik na-aga n'ihu, mmiri dị na smearing film dialysis si na fim ahụ pụta ma na-akwaga na ịsa ahụ iji kpoo ihe nkiri ahụ. Nke a bụ electroosmosis. Electroosmosis na-atụgharị ihe nkiri mkpuchi hydrophilic ka ọ bụrụ ihe nkiri mkpuchi hydrophobic, na akpịrị ịkpọ nkụ na-eme ka ihe mkpuchi ahụ sie ike. Enwere ike imetụ agba mmiri mmiri mgbe igwu mmiri na ezigbo electro-osmosis electrophoretic agba ma ghara ịrapara. Ị nwere ike ikpochapụ mmiri mmiri ịsa ahụ na-arapara na ihe nkiri agba mmiri na mmiri.

Njirimara nke Electrocoating

Ihe nkiri agba Electrophoretic nwere uru nke zuru oke, ịdị n'otu, ịdị larịị na mkpuchi dị larịị. The ike, adhesion, corrosion resistance, mmetụta arụmọrụ, na permeability nke electrophoretic paint film dị nnọọ mma karịa ndị ọzọ mkpuchi usoro.

(1) A na-eji agba mmiri na-agbaze mmiri, a na-eji mmiri eme ihe dị ka ihe na-agbaze, nke na-echekwa ọtụtụ ihe mgbaze organic, na-ebelata mmetọ ikuku na ihe ize ndụ gburugburu ebe obibi, dị mma na ịdị ọcha, na-ezere ihe ize ndụ nke ọkụ;

(2) Ihe osise eserese dị elu, nkwụsị nke agba dị ntakịrị, na ntinye nke agba nwere ike iru 90% ruo 95%;

(3) Ihe nkiri mkpuchi mkpuchi bụ otu, adhesion siri ike, na mkpuchi mkpuchi dị mma. Nke ọ bụla akụkụ nke workpiece, dị ka n'ime oyi akwa, depressions, welds, wdg, nwere ike nweta a edo na-eji ire ụtọ mkpuchi film, nke na-edozi nsogbu nke ọzọ mkpuchi ụzọ maka mgbagwoju ekara workpieces. Nsogbu eserese;

(4) The mmepụta arụmọrụ dị elu, na-ewu nwere ike na-aghọta akpaka na-aga n'ihu mmepụta, nke ukwuu mma ọrụ arụmọrụ;

(5) Ngwá ọrụ dị mgbagwoju anya, ego ntinye ego na-akwụ ụgwọ dị elu, ike oriri dị ukwuu, okpomọkụ a chọrọ maka ihicha na ọgwụgwọ dị elu, njikwa nke agba na eserese dị mgbagwoju anya, ọnọdụ ihe owuwu ahụ siri ike, a na-achọkwa ọgwụgwọ mmiri mkpofu. ;

(6) Naanị agba agba mmiri nwere ike iji mee ihe, na agba enweghị ike ịgbanwe n'oge usoro mkpuchi. Nkwụsi ike nke agba adịghị mfe ịchịkwa mgbe nchekwa ruo ogologo oge.

(7) Ngwá ọrụ mkpuchi electrophoretic dị mgbagwoju anya na nkà na ụzụ dị elu, nke kwesịrị ekwesị maka mmepụta nke agba agba.

Oke nke Electrocoating

(1) Ọ na-adabara naanị maka mkpuchi primer nke ihe ndị na-eduzi ihe dị ka akụkụ igwe nke ígwè ferrous na ọla ndị na-abụghị ígwè. Enweghị ike iji usoro a kpuchie ihe ndị na-adịghị mma dị ka osisi, plastik, ákwà, wdg.

(2) Usoro mkpuchi electrophoretic adịghị mma maka ihe ndị a na-ekpuchi ihe mejupụtara nke ọtụtụ ọla, ma ọ bụrụ na njirimara electrophoresis dị iche.

(3) Enweghị ike iji usoro mkpuchi electrophoretic mee ihe maka ihe ndị a na-ekpuchi anya na-enweghị ike ịnagide okpomọkụ dị elu.

(4) Mkpuchi Electrophoretic adịghị mma maka mkpuchi nwere oke chọrọ na agba. Ekwesịrị ịcha mkpuchi electrophoretic nke agba dị iche iche na oghere dị iche iche.

(5) Electrophoretic mkpuchi adịghị atụ aro maka obere-batch mmepụta (oge ọhụrụ nke bat bụ ihe karịrị ọnwa 6), n'ihi na mmeghari ọsọ nke bat ahụ na-adị ngwa ngwa, resin na bat ahụ na-aka nká na ihe mgbaze na-agbanwe. nke ukwuu. Ebe ịsa ahụ adịghị eguzosi ike.

Nzọụkwụ nke Electrocoating

(1) N'ihi na electrophoretic mkpuchi nke izugbe metal na-ebupụta, usoro eruba bụ: tupu ihicha → degreasing → mmiri ịsacha → iwepụ nchara → mmiri ịsacha → neutralization → mmiri ịsacha → phosphating → mmiri ịsacha → passivation → electrophoretic mkpuchi → tank top Cleaning → ultrafiltration mmiri ịsacha → ihicha → offline.

(2) Mgbochi na pretreatment nke ihe mkpuchi nwere mmetụta dị ukwuu na ihe nkiri mkpuchi electrophoretic. A na-eji aja aja ma ọ bụ ịgbawa agbawa agbachapụ ihe nkedo ọla n'ozuzu, a na-eji yarn owu wepụ uzuzu na-ese n'elu ihe arụrụ arụ, a na-ejikwa ájá na-ewepụ ihe nchara nchara na ihe ndị ọzọ dị n'elu. A na-emeso elu ígwè ahụ site na nkwụsị na iwepụ nchara. Mgbe ihe ndị dị n'elu chọrọ dị elu, a chọrọ ọgwụgwọ phosphating na passivation elu. Ferrous metal workpieces ga-phosphated tupu anodic electrophoresis, ma ọ bụghị corrosion iguzogide nke agba film ga-adịghị mma. Na ọgwụgwọ phosphating, a na-ahọrọ ihe nkiri phosphating nnu zinc n'ozuzu, nke nwere ihe dị ka 1 ruo 2 μm, na ihe nkiri phosphate chọrọ ka ọ nwee kristal dị mma na nke edo.

(3) N'ime usoro nzacha, a na-anabatakarị nzacha nke mbụ, na nzacha bụ nhazi akpa ntupu. A na-ebufe agba electrophoretic na nzacha site na mgbapụta kwụ ọtọ maka nzacha. N'ịtụle okirikiri nnọchi anya zuru oke na ịdị mma nke ihe nkiri agba, akpa nzacha nwere oke nha nke 50μm kacha mma. Ọ nwere ike ọ bụghị nanị izute àgwà chọrọ nke ihe nkiri agba, kamakwa dozie nsogbu nke nzacha akpa nzacha.

(4) Ogo nke usoro mgbasa ozi nke mkpuchi electrophoretic na-emetụta kpọmkwem nkwụsi ike nke bat na àgwà nke ihe nkiri agba. Ịba ụba nke mgbasa ozi na-ebelata mmiri ozuzo na afụ nke mmiri mmiri ịsa ahụ; Otú ọ dị, ịka nká nke mmiri mmiri ịsa ahụ na-eme ngwa ngwa, ike ike na-abawanye, na nkwụsi ike nke mmiri mmiri ịsa ahụ na-akawanye njọ. Ọ dị mma ijikwa oge okirikiri nke mmiri mmiri tank ruo 6-8 ugboro / h, nke ọ bụghị nanị na-ekwe nkwa ịdị mma nke ihe nkiri agba, kamakwa na-eme ka ọrụ kwụsiri ike nke mmiri mmiri tank.

(5) Ka oge mmepụta na-abawanye, mgbochi nke diaphragm anode ga-abawanye na voltaji na-arụ ọrụ dị irè ga-ebelata. Ya mere, na mmepụta, voltaji na-arụ ọrụ nke ike ọkụ kwesịrị iji nwayọọ nwayọọ na-abawanye dị ka voltaji na-efu iji kwụọ ụgwọ voltaji nke diaphragm anode.

(6) The ultrafiltration usoro na-achịkwa ịta nke adịghị ọcha ion wetara site workpiece iji hụ na àgwà nke mkpuchi. N'ime ọrụ nke usoro a, ekwesịrị iburu n'uche na ozugbo usoro ahụ na-arụ ọrụ, ọ ga-agba ọsọ na-aga n'ihu ma na-amachibido iwu ka ọ na-agba ọsọ n'oge na-adịghị anya iji gbochie akpụkpọ ahụ ultrafiltration ihicha. Resin a mịrị amị na pigmenti na-agbaso akpụkpọ ahụ ultrafiltration na enweghị ike ihicha ya nke ọma, nke ga-emetụta oke mmiri na ndụ ọrụ nke akpụkpọ ahụ ultrafiltration. Ọnụego mmepụta mmiri nke akpụkpọ ahụ ultrafiltration na-egosi ọnọdụ ala na oge na-agba ọsọ. Ekwesịrị ịsacha ya otu ugboro maka ụbọchị 30-40 nke ọrụ na-aga n'ihu iji hụ na mmiri ultrafiltration chọrọ maka leaching ultrafiltration na ịsacha.

(7) Usoro mkpuchi electrophoretic dị mma maka usoro mmepụta nke ọnụ ọgụgụ dị ukwuu nke ahịrị mgbakọ. Oge mmeghari ohuru nke bat electrophoresis kwesịrị ịdị n'ime ọnwa 3. Nlekọta sayensị nke ịsa ahụ dị oke mkpa. A na-anwale paramita dị iche iche nke bat ahụ mgbe niile, a na-edozikwa bat ahụ ma dochie ya dịka nsonaazụ ule si dị. N'ozuzu, a na-atụle paramita nke ngwọta bat ahụ ugboro ugboro: uru pH, ọdịnaya siri ike na conductivity nke ngwọta electrophoresis, ngwọta ultrafiltration na ultrafiltration ihicha ngwọta, anion (anode) ngwọta polar, na-ekesa ude mmiri na deionization ngwọta ozugbo. otu ụbọchị; Ogo ntọala, ihe mgbaze organic, yana nnwale obere ụlọ nyocha ugboro abụọ n'izu.

(8) Maka njikwa mma nke ihe nkiri agba, a ga-enyocha ịdị n'otu na ọkpụrụkpụ nke ihe nkiri agba ugboro ugboro, na ọdịdị ahụ ekwesịghị inwe pinholes, sagging, peel orange, wrinkles, wdg. Na-enyocha mgbe niile na anụ ahụ na kemịkal. ihe na-egosi dị ka nchikota na corrosion iguzogide ihe nkiri mkpuchi. Usoro nleba anya dabara n'ụkpụrụ nyocha nke onye nrụpụta, na n'ozuzu ọ dị mkpa ka enyocha ogbe ọ bụla.

Ọgwụgwọ Elu Tupu Electrophoresis

The elu ọgwụgwọ nke workpiece tupu mkpuchi bụ akụkụ dị mkpa nke electrophoretic mkpuchi, tumadi metụtara degreasing, nchara mwepụ, elu conditioning, phosphating na ndị ọzọ Filiks. Ọdịdị nke ọgwụgwọ ya ọ bụghị nanị na-emetụta ọdịdị nke ihe nkiri ahụ, na-ebelata ọrụ mgbochi corrosion, ma na-ebibikwa nkwụsi ike nke ngwọta agba. Ya mere, maka elu nke workpiece tupu eserese, ọ na-achọrọ na-free nke mmanụ stains, nchara akara, ọ dịghị pretreatment chemicals na phosphating sedimentation, wdg, na phosphating film nwere ok na edo kristal. Banyere usoro ọgwụgwọ dị iche iche, anyị agaghị atụle ha n'otu n'otu, mana naanị tinye isi ihe ole na ole nlebara anya:

1) Ọ bụrụ na nkwụsịtụ na nchara adịghị ọcha, ọ bụghị naanị na ọ ga-emetụta mmepụta nke ihe nkiri phosphating, kamakwa ọ na-emetụta ike njikọ, ihe ịchọ mma na nguzogide corrosion nke mkpuchi. Ihe nkiri agba na-adịkarị mfe ịkụda na pinholes.

2) Phosphating: Ebumnuche bụ imeziwanye adhesion na mgbochi corrosion nke ihe nkiri electrophoretic. Ọrụ ya bụ nke a:

(1) N'ihi mmetụta anụ ahụ na nke kemịkal, a na-eme ka adhesion nke ihe nkiri mkpuchi organic na mkpụrụ.

(2) Ihe nkiri phosphating na-atụgharị n'elu igwe site na onye nduzi dị mma gaa na onye nduzi na-adịghị mma, si otú ahụ na-egbochi ịmepụta micro-batrị na elu ígwè, na-egbochi nrụrụ nke mkpuchi nke ọma, na-abawanye nkwụsị nke corrosion na mmiri na-eguzogide mmiri. mkpuchi. Tụkwasị na nke ahụ, ọ bụ naanị na ndabere nke ala nke ọma na nkwụsịtụ, enwere ike ịmepụta ihe nkiri phosphating na-eju afọ n'elu ebe dị ọcha, uwe, na griiz. Site na akụkụ a, ihe nkiri phosphating n'onwe ya bụ ihe kachasị emetụ n'ahụ na nke a pụrụ ịdabere na ya na mmetụta nke usoro nhazi ahụ.

3) Ịsacha: Ọdịdị nke ịsacha na ọkwa ọ bụla nke pretreatment ga-enwe mmetụta dị ukwuu n'ịdị mma nke ihe niile pretreatment na agba ihe nkiri. Nhicha mmiri ikpeazụ deionized tupu eserese, jide n'aka na ihe na-eme ka mmiri na-asọpụta nke ihe mkpuchi ahụ adịghị elu karịa 30μs / cm. Nhicha adịghị ọcha, dị ka workpiece:

(1) acid fọdụrụnụ, mmiri mmiri kemịkalụ phosphating, flocculation nke resin n'ime mmiri agba agba, na nkwụsi ike na-emebi emebi;

(2) Ihe ndị ọzọ fọdụrụnụ (nyocha mmanụ, uzuzu), oghere nkwụsị, ihe ndị ọzọ na ntụpọ ndị ọzọ na ihe nkiri agba;

(3) Electrolytes fọdụrụnụ na nnu na-eduga na mmeghachi omume electrolysis ka njọ ma na-emepụta pinholes na ọrịa ndị ọzọ.

Oge nzipu: Eprel 17-2021