Ihe nkedo igwe anaghị agba nchara nke OEM mepụtara site na ntinye ntinye ego na-efu efu naCNC ọrụ igwe. A na-eji igwe anaghị agba nchara AISI 316 / CF8M na-emepụta ụlọ mgbapụta igwe anaghị agba nchara ma ọ bụ mkpuchi njedebe n'ihi arụmọrụ ya dị mma.

Igwe anaghị agba nchara nwere opekempe chromium ọdịnaya nke 10.5%, na-eme ka ọ na-eguzogide ọgwụ na gburugburu mmiri mmiri na-emebi emebi yana oxidation. Ọ bụ nke ukwuu corrosion eguzogide na eyi na-eguzogide ọgwụ, na-enye magburu onwe machinability, na a maara nke ọma maka aesthetic ọdịdị. Ihe nkedo ntinye ego igwe anaghị agba nchara bụ "na-eguzogide corrosion" mgbe ejiri ya na gburugburu mmiri mmiri na vapors n'okpuru 1200°F (650°C) yana "ọkụ na-eguzogide" mgbe ejiri ya karịa okpomọkụ a.

Ihe mgbakwasị ụkwụ nke ihe nkedo nickel-base ma ọ bụ igwe anaghị agba nchara bụ chromium, nickel, na molybdenum (ma ọ bụ "moly"). Akụkụ atọ ndị a ga-ekpebi nhazi ọka nke ihe nkedo na ihe eji arụ ọrụ ma bụrụ ihe enyemaka n'ikike nkedo ahụ iji luso okpomọkụ, iyi, na corrosion ọgụ.

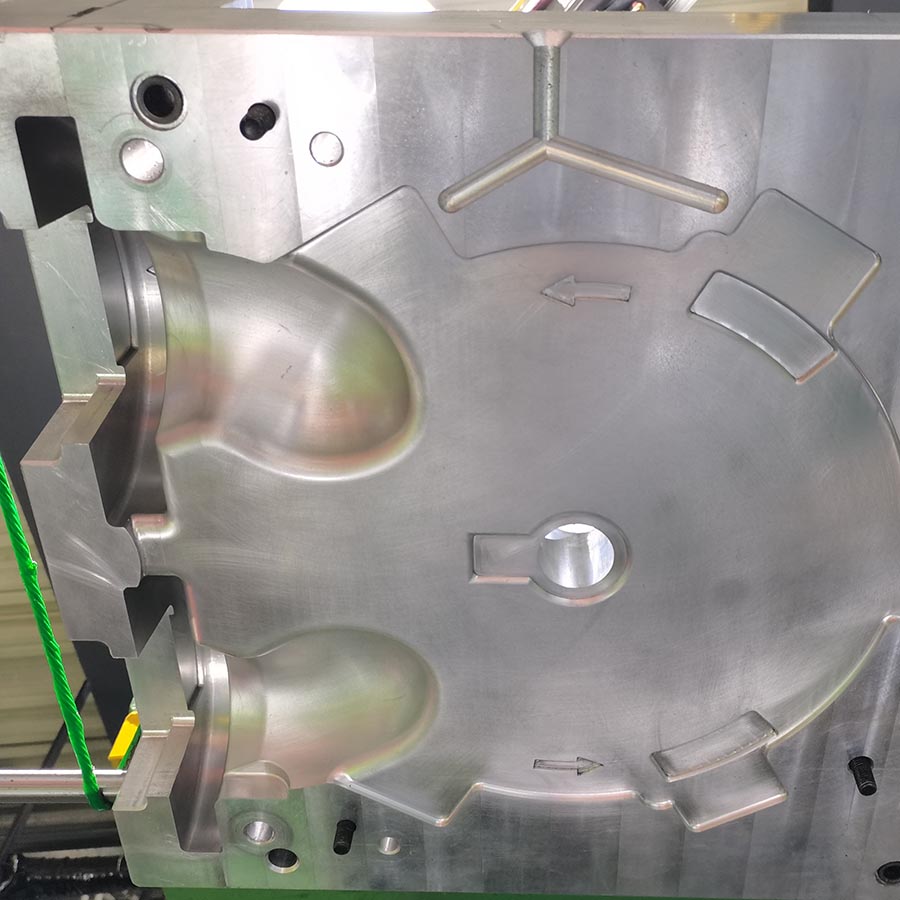

Ụlọ ọrụ anyị nwere ike ịmepụtaomenala igwe anaghị agba nchara itinye ego nkedona dakọtara na gị kpọmkwem imewe nkọwa. Maka akụkụ sitere na iri iri gram ruo iri kilogram ma ọ bụ karịa, anyị na-enye nnabata siri ike yana akụkụ na-agbanwe agbanwe na akụkụ na-agbanwe agbanwe.

Ọtụtụ mgbe, igwe anaghị agba nchara kwesịrị ịwụ yausoro nkedo nkenke itinye egona silica sol dị ka njikọ. Ihe nkedo silica sol igwe anaghị agba nchara nwere ọkwa dị elu nke oke elu yana arụmọrụ.

N'ihi njirimara anụ ahụ pụrụ iche, nkedo igwe anaghị agba nchara na-ewu ewu n'ọtụtụ ngwa ngwa, ọkachasị ndị nọ na gburugburu ebe siri ike. Ahịa ndị a na-ahụkarị maka nkedo ntinye igwe anaghị agba nchara gụnyere mmanụ na gas, ike mmiri, ụgbọ njem, sistemu hydraulic, ụlọ ọrụ nri, ngwaike na mkpọchi, ọrụ ugbo... wdg.

▶ Ikike nkeỤlọ ọrụ nkedo itinye ego

• Oke kachasị: 1,000 mm × 800 mm × 500 mm

• Oke arọ: 0,5 n'arọ - 100 n'arọ

• Ike kwa afọ: tọn 2,000

• Ihe nkwekọ maka ụlọ Shell: Silica Sol, Glass Water na ngwakọta ha.

• Nkwenye: Na Arịrịọ.

▶ Isi usoro nke itinye ntinye ego

• Ụdị & Ngwá Ọrụ Imepụta → Metal Die Ime → Wax Injection → Slurry Assembly → Shell Building → De-Waxing → Chemical Composition Analysis → Agbaze & Ịwụ → Nchacha, Egweri & Mgbawa → Post nhazi ma ọ bụ mbukota maka Mbupu

▶ Otu anyị si enyochaIhe nkedo wax furu efu

• Spectrographic na ntuziaka quantitative analysis

• Metallographic analysis

• Brinell, Rockwell na Vickers nyocha ike siri ike

• Mechanical onwunwe nyocha

• Nnwale mmetụta okpomọkụ dị ala na nke nkịtị

• Nnyocha ịdị ọcha

• Nyocha UT, MT na RT

▶ Usoro nkedo mgbe emechara

• Deburring & Nhicha

• Mgbawa agbawa / ájá peening

• Ọgwụgwọ okpomọkụ: Normalization, Quench, Tempering, Carburization, Nitriding

• Ngwọta dị n'elu: Passivation, Anodizing, Electroplating, Hot Zinc Plating, Zinc Plating, Nickel Plating, Polishing, Electro-Polishing, Painting, GeoMet, Zintec.

• Igwe eji eme ihe: Ntugharị, igwe-egwe ọka, ịsụ mmiri, ịkụ ihe, ịsọpụrụ, egweri.

▶ Uru nke Usoro ntinye ego:

• Magburu onwe na ire ụtọ elu imecha

• Nkwenye akụkụ siri ike.

• Ụdị mgbagwoju anya na mgbagwoju anya nwere mgbanwe nhazi

• Ike ịwụ mgbidi dị gịrịgịrị ya mere ihe nkedo dị mfe karị

• Nhọrọ sara mbara nke nkedo ọla na alloys (ferrous na ndị na-abụghị igwe)

• Ọ dịghị mkpa ka Draft na-akpụ akpụ imewe.

• Belata mkpa maka igwe nke abụọ.

• Ihe mkpofu ihe dị ala.