ChinaOnye na-eweta ọrụ igwe CNCiji nweta igwe anaghị agba nchara dị ka eserese gị na ihe ndị a chọrọ, nke a na-eji maka ụlọ mgbapụta na ahụ.

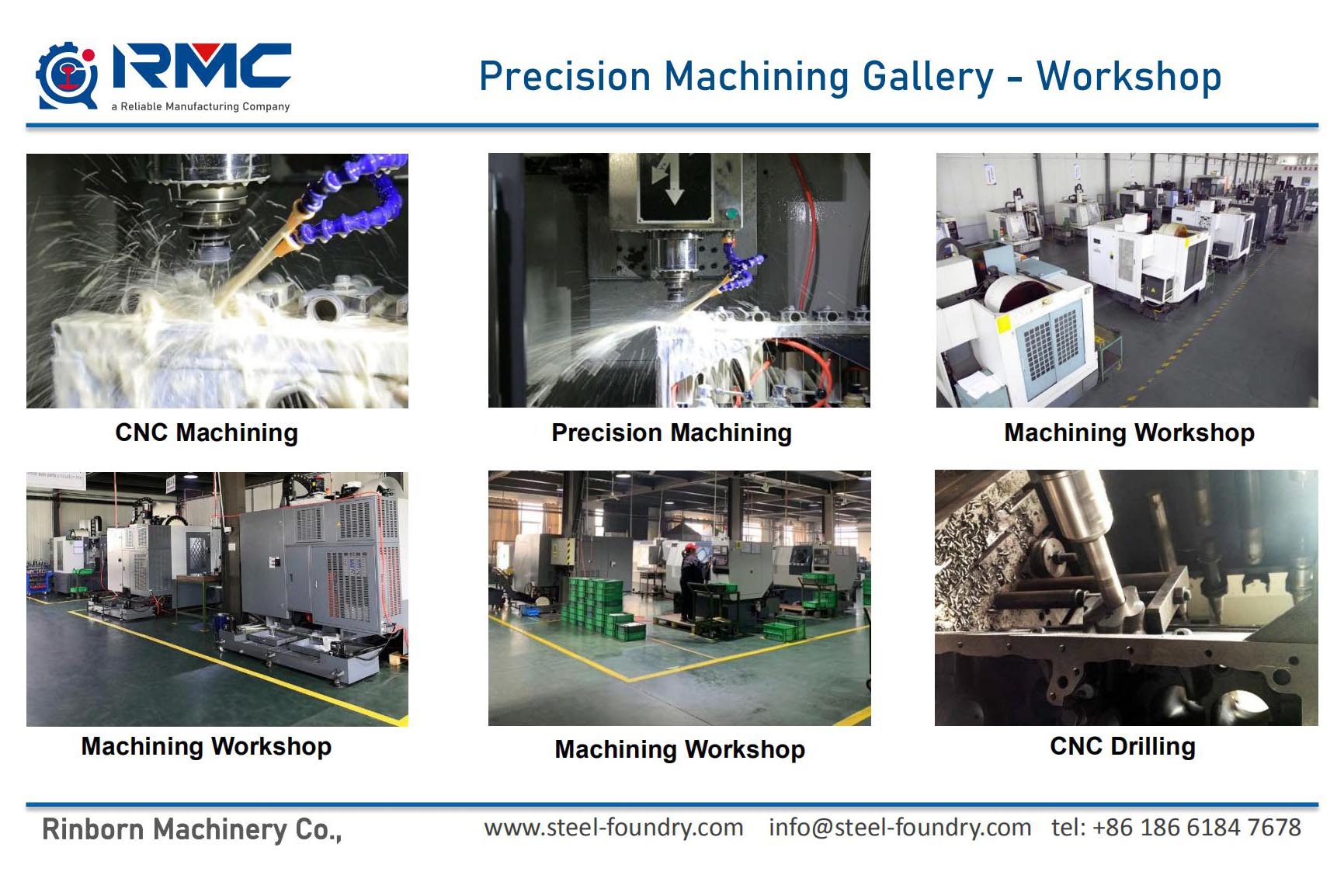

CNC machining na-ezo aka na usoro igwe na-aga n'ihu site na njikwa ọnụọgụ kọmputa (CNC maka mkpụmkpụ). Ndị CNC na-enyere ya aka iru oke ziri ezi yana ọnụ ahịa obere ọrụ. Machining bụ usoro ọ bụla dị iche iche nke a na-egbutu ihe eji eme ihe n'ime ụdị ikpeazụ a chọrọ site na usoro iwepụ ihe eji achịkwa. Usoro ndị nwere isiokwu a na-ahụkarị, mwepụ ihe a na-achịkwa, bụ nke a na-akpọkọta ọnụ dị ka mmepụta ihe na-emepụta ihe, dị iche na usoro nke mgbakwunye ihe a na-achịkwa, nke a maara dị ka mmepụta ihe mgbakwunye.

Kpọmkwem ihe akụkụ "a na-achịkwa" nke nkọwa ahụ nwere ike ịdịgasị iche, ma ọ fọrọ nke nta ka ọ bụrụ mgbe niile na-egosi iji ngwá ọrụ igwe (na mgbakwunye na naanị ngwá ọrụ ike na ngwaọrụ aka). Nke a bụ usoro eji emepụta ọtụtụ ngwaahịa igwe, mana enwere ike iji ya mee ihe dịka osisi, plastik, seramiiki, na ihe ndị mejupụtara. Igwe eji eme CNC na-ekpuchi ọtụtụ usoro dị iche iche dị ka igwe igwe, ntụgharị, ịcha mmiri, mkpọpu mmiri, ịkwanye, ịcha ọka ... wdg.

| Ike nrụpụta nke ọma CNC | ||||

| Ụlọ ọrụ | Ọnụọgụ | Oke Oke | Ike kwa afọ | Izi ezi izugbe |

| Ebe nrụpụta kwụ ọtọ (VMC) | 48 setịpụ | 1500mm × 1000mm × 800mm | 6000 ton ma ọ bụ 300000 iberibe | ±0.005 |

| Horizontal Machining Center (VMC) | 12 tent | 1200mm × 800mm × 600mm | 2000 tọn ma ọ bụ 100000 iberibe | ±0.005 |

| Igwe CNC | 60 setịpụ | Max na-atụgharị dia. φ600mm | 5000 tọn ma ọ bụ 600000 iberibe | |

| Ọkọlọtọ Excutive nke ntachi obi nkedo: ISO 8062 2013, ISO 2768, GOST 26645 (Russia) ma ọ bụ GBT 6414 (China). | ||||

A na-emepụta ebe a na-emepụta ihe site na igwe igwe igwe CNC. Nnukwu ihe dị iche site na igwe igwe igwe CNC bụ na ebe a na-emepụta ihe nwere ikike ịgbanwe ngwa igwe na-akpaghị aka. Site na ịwụnye ngwá ọrụ maka ebumnuche dị iche iche na magazin ngwá ọrụ ahụ, ngwá ọrụ na-arụ ọrụ na spindle nwere ike ịgbanwe site na onye na-agbanwe ngwá ọrụ na-akpaghị aka na otu clamping iji ghọta ọtụtụ atụmatụ nhazi.

Ụlọ ọrụ CNC na-arụ ọrụ na-arụ ọrụ nke ọma na-arụ ọrụ nke ọma na-arụ ọrụ nke ọma na usoro CNC ma dị mma maka nhazi akụkụ dị mgbagwoju anya. Ebe CNC machining center bụ ugbu a otu n'ime ngwa igwe CNC a na-ejikarị eme ihe n'ụwa nwere ikike nhazi zuru oke. Ọ nwere ike mezue ọdịnaya nhazi ọzọ mgbe ejiri eriri workpiece ahụ mechie n'otu oge. Nhazi nhazi dị elu. N'ihi na ogbe workpieces na ọkara nhazi ihe isi ike, ya arụmọrụ bụ 5-10 ugboro nke ndị nkịtị akụrụngwa, karịsịa ọ nwere ike mezue Ọtụtụ nhazi na-enweghị ike imecha site nkịtị ngwá bụ ndị ọzọ dabara maka otu-ibe nhazi na ihe mgbagwoju shapes na elu nkenke chọrọ ma ọ bụ. maka obere na ọkara mmepụta nke otutu iche. Ọ na-etinye uche n'ọrụ nke igwe igwe, na-agwụ ike, ịkụ ala, ịkụ aka na ịcha eri n'otu ngwaọrụ, ka o wee nwee ụzọ nkà na ụzụ dị iche iche.

A na-ekewa ebe a na-eji ígwè ọrụ n'ime ebe a na-eji igwe kwụ ọtọ na kwụ ọtọ dịka ọnọdụ ha na-adị n'oge a na-eji spindle machining. Nkewa dị ka usoro ojiji: na-agwụ ike na-egwe ọka center, compound machining center. Dị ka pụrụ iche nkewa nke ọrụ, e nwere: otu workbench, double workbench na multi-workbench machining center. Ebe a na-emepụta ihe na otu-axis, dual-axis, axis atọ, axis anọ, axis ise na isi isi mgbanwe, wdg.

CNC machining bụ ụdị nke ziri ezi machining site CNC igwe dị ka elu machining centers nke nwere n'elu njedebe 5 axis machining center, 4 axis okpukpu abụọ n'elu ikpo okwu machining center, ma ọ bụ CNC mbịne lathes nke nwekwara ike ịzụlite na CNC mbịne center nwere ikike nke na-agbanwe ihe ọzọ. karịa 15 cutters n'ime otu njide mgbanwe; Igwe igwe igwe igwe CNC na ebe a na-egwuputa ihe na ebe a na-apịpụta ihe. Nkedo nkenke enwetalarị ụdị nke a chọrọ, yabụ ọ na-echekwa ọtụtụ igwe ma e jiri ya tụnyere igwe si na profaịlụ nchara ozugbo. Ọzọkwa n'ihi nke a, anyị na-emekarị na-atụle machining elu na kwesịrị ekwesị machining ohere tupu nkedo. Ihe anyị na-azụta mgbe niile bụ ịrụpụta ihe nkedo raw yana ịse ihe eji arụ ọrụ iji kọwapụta ebe ị na-arụ ọrụ na ikike ịnya ihe na eserese ahụ.

RMC itinye ego nkedo Fondry nwere 4 axis machining Centers, 15 tent nke CNC na-atụgharị lathes na 3 tent nke cnc egwe ọka igwe, tinyere nnyemaaka nkịtị vasatail ntụgharị, egwe ọka, ịme ọpịpị, mkpọ ala na egweri igwe, anyị nwere ike nke machining fọrọ nke nta niile. ụdị nkedo ígwè.

| Nha nhata nke Cast Alloy Steel sitere na ahịa dị iche iche | |||||||||

| Otu dị iche iche | AISI | W-nkwakọba | DIN | BS | SS | AFNOR | UNE / IHA | JIS | UNI |

| Alloy Alloy Steel | 9255 | 1.0904 | 55 Si 7 | 250 A53 | 2090 | 55 S7 | 56Si7 | - | 5SSi8 |

| 1335 | 1.1167 | 36 nde 5 | 150 M 36 | 2120 | 40 M5 | 36 nde 5 | SMn 438 (H) | - | |

| 1330 | 1.1170 | 28 nde 6 | 150 M28 | - | 20 M5 | - | SCMn1 | C28MN | |

| P4 | 1.2341 | X6 CRMo 4 | - | - | - | - | - | - | |

| 52100 | 1.3505 | 100 cr 6 | 534 nke 99 | 2258 | 100C6 | F.131 | SUJ 2 | 100Cr6 | |

| A204A | 1.5415 | 15 Mo 3 | 1501 240 | 2912 | 15 D3 | 16 Mo3 | STBA 12 | 16Mo3 KW | |

| 8620 | 1.6523 | 21 NiCrMo 2 | 805 M20 | 2506 | 20 NCD 2 | F.1522 | SNCM 220 (H) | 20NiCrMo2 | |

| 8740 | 1.6546 | 40NiCrMo22 | 311-ụdị 7 | - | 40 NCD 2 | F.129 | SNCM 240 | 40NiCrMo2(KB) | |

| - | 1.6587 | 17CrNiMo6 | 820A 16 | - | 18 NCD 6 | 14NiCrMo13 | - | - | |

| 5132 | 1.7033 | 34 cr 4 | 530 A32 | - | 32C4 | 35Cr4 | SCr430 (H) | 34Cr4 (KB) | |

| 5140 | 1.7035 | 41 cr 4 | 530 A40 | - | 42C2 | 42 cr 4 | SCr 440 (H) | 40Cr4 | |

| 5140 | 1.7035 | 41 cr 4 | 530 A40 | - | 42C2 | 42 cr 4 | SCr 440 (H) | 41Cr4 KB | |

| 5140 | 1.7045 | 42 cr 4 | 530 A40 | 2245 | 42C 4 TS | F.1207 | SC440 | - | |

| 5115 | 1.7131 | 16 MnCr 5 | (527 M 20) | 2511 | 16 MC 5 | F.1516 | - | 16MnCr5 | |

| 5155 | 1.7176 | 55 cr 3 | 527 nke 60 | 2253 | 55C3 | - | SUP 9 (A) | 55Cr3 | |

| 4130 | 1.7218 | 25 crMo 4 | 1717CDS 110 | 2225 | 25 CD 4 | F.1251/55Cr3 | SCM 420 / SCM430 | 25CrMo4 (KB) | |

| 4135 (4137) | 1.7220 | 35 CRMo 4 | 708 A37 | 2234 | 35 CD4 | 34 CRMo 4 | SCM 432 | 34CrMo4KB | |

| 4142 | 1.7223 | 41 crMo 4 | 708 M40 | 2244 | 42 CD 4 TS | 42 CRMo 4 | SCM 440 | 41 crMo 4 | |

| 4140 | 1.7225 | 42 CRMo 4 | 708 M40 | 2244 | 40 CD 4 | F.1252 | SCM 440 | 40CrMo4 | |

| 4137 | 1.7225 | 42 CRMo 4 | 708 M40 | 2244 | 42 CD 4 | F.1252 | SCM 440 | 42CrMo4 | |

| A387 12-2 | 1.7337 | 16 crMo 4 4 | 1501 620 | 2216 | 15 CD 4.5 | - | - | 12CrMo910 | |

| - | 1.7361 | 32CrMo12 | 722 M 24 | 2240 | 30 CD 12 | F.124.A | - | 30CrMo12 | |

| A182 F-22 | 1.7380 | 10CrMo9 10 | 1501 622 | 2218 | 12 CD 9, 10 | F.155 / TU.H | - | 12CrMo9 10 | |

| 6150 | 1.8159 | 50 crV 4 | 735 A50 | 2230 | 50 CV 4 | F.143 | SUP 10 | 50CrV4 | |

| - | 1.8515 | 31 crMo 12 | 722 M 24 | 2240 | 30 CD 12 | F.1712 | - | 30CrMo12 | |

| - | - | - | - | - | - | - | - | - | |

| Alloy Steel Ọkara | W1 | 1.1545 | C105W1 | BW1A | 1880 | Y 105 | F.5118 | SK 3 | C100 KU |

| L3 | 1.2067 | 100Cr6 | BL 3 | (2140) | Y 100C 6 | F.520 L | - | - | |

| L2 | 1.2210 | 115 crV 3 | - | - | - | - | - | - | |

| P20 + S | 1.2312 | 40CrMnMoS 8 6 | - | - | 40 CMD 8 +S | X210CrW12 | - | - | |

| - | 1.2419 | 105WCr6 | - | 2140 | 105W C 13 | F.5233 | SKS 31 | 107WCr5KU | |

| O1 | 1.2510 | 100MnCrW 4 | BO1 | - | 90MnWCrV5 | F.5220 | (SK53) | 95MnWCr5KU | |

| S1 | 1.2542 | 45 WCrV 7 | BS1 | 2710 | 55W20 | F.5241 | - | 45WCrV8KU | |

| 4340 | 1.6582 | 34 CrNiMo 6 | 817 M40 | 2541 | 35 NCD 6 | F.1280 | SNCM 447 | 35NiCrMo6KB | |

| 5120 | 1.7147 | 20 MnCr 5 | - | - | 20 MC 5 | - | - | - | |

| - | - | - | - | - | - | - | - | - | |

| Ngwá ọrụ na High Alloy Steel | D3 | 1.2080 | X210 cr 12 | BD3 | 2710 | Z200C 12 | F.5212 | SKD 1 | X210Cr13KU |

| P20 | 1.2311 | 40CrMnMo 7 | - | - | 40 CMD 8 | F.5263 | - | - | |

| H13 | 1.2344 | X40CrMoV 5 1 | BH13 | 2242 | Z 40 CDV 5 | F.5318 | SKD 61 | X40CrMoV511KU | |

| A2 | 1.2363 | X100 CrMoV 5 1 | BA2 | 2260 | Z 100 CDV 5 | F.5227 | SKD 12 | X100CrMoV51KU | |

| D2 | 1.2379 | X155 CrMoV 12 1 | BD2 | 2310 | Z 160 CDV 12 | F.520.A | SKD11 | X155CrVMo121KU | |

| D4 (D6) | 1.2436 | X210 CRW 12 | BD6 | 2312 | Z 200 CD 12 | F.5213 | SKD 2 | X215CrW121KU | |

| H21 | 1.2581 | X30WCrV9 3 | BH21 | - | Z 30 WCV 9 | F.526 | SKD5 | X30WCrV 9 3 KU | |

| L6 | 1.2713 | 55NiCrMoV 6 | - | - | 55 NCDV 7 | F.520.S | SKT4 | - | |

| M 35 | 1.3243 | S6/5/2/5 | BM 35 | 2723 | 6-5-2-5 | F.5613 | SKH 55 | HS6-5-5 | |

| M 2 | 1.3343 | S6/5/2 | BM2 | 2722 | Z 85 WDCV | F.5603 | SKH 51 | HS6-5-2-2 | |

| M 7 | 1.3348 | S2/9/2 | - | 2782 | 292 | - | - | HS2-9-2 | |

| HW 3 | 1.4718 | X45CrSi 9 3 | 401 S45 | - | Z 45 CS 9 | F.3220 | SUH1 | X45CrSi8 | |

| - | 1.7321 | 20MoCr 4 | - | 2625 | - | F.1523 | - | 30CrMo4 | |

| Steel ike dị elu | A128 (A) | 1.3401 | G-X120 nde 12 | BW10 | 2183 | Z 120 M 12 | F.8251 | SCMnH 1 | GX120Mn12 |

Ike nkeỤlọ ọrụ nkedo itinye ego:

• Oke kachasị: 1,000 mm × 800 mm × 500 mm

• Oke arọ: 0,5 n'arọ - 100 n'arọ

• Ike kwa afọ: tọn 2,000

• Ihe nkwekọ maka ụlọ Shell: Silica Sol, Glass Water na ngwakọta ha.

• Nkwenye: Na Arịrịọ.

Uru nkeNgwa nkedo itinye ego:

- Magburu onwe ma dị ire ụtọ elu imecha

- Nkwenye akụkụ siri ike.

- Ụdị mgbagwoju anya na mgbagwoju anya nwere mgbanwe imewe

- Ikike ịwụ mgbidi ndị dị mkpa ya mere ihe nkedo dị ọkụ

- Nhọrọ sara mbara nke nkedo ọla na alloys (ferrous na ndị na-abụghị igwe)

- Ọ dịghị mkpa ka Draft na ebu imewe.

- Belata mkpa nke abụọ machining.

- obere ihe mkpofu.

| Ngwa maka itinye ego na nkedoỤlọ ọrụ CNCna RMC Foundry | |||

| Otu | China ọkwa | Ọkwa US | Germany ọkwa |

| Ferritic igwe anaghị agba nchara | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic igwe anaghị agba nchara | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic igwe anaghị agba nchara | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404.4.1. 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Mmiri ozuzo na-eme ka igwe anaghị agba nchara | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex igwe anaghị agba nchara | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Ngwá Ọrụ Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Igwe na-eguzogide okpomọkụ | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX (66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Aluminom Alloy | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Alloy ọla kọpa | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-base Alloy | UMC50, 670, Ọkwa 31 | 2,4778 | |

A na-akpọkwa machining nkenke, igwe CNC nwere ike iru izi ezi dị oke elu na nnabata geometric na nnabata akụkụ. Site na igwe CNC anyị yana Horizontal Machining Centers (HMC) na Vertical Machining Centre (VMC), anyị nwere ike nweta akara ule nnabata niile achọrọ.

| anabata nnabata nke itinye ego | |||

| Inches | Millimeters | ||

| Akụkụ | Ndidi | Akụkụ | Ndidi |

| Ruo 0,500 | ±.004" | Ruo 12.0 | ± 0.10mm |

| 0.500 ruo 1.000" | ±.006" | 12.0 ruo 25.0 | ± 0.15mm |

| 1.000 ruo 1.500” | ±.008" | 25.0 ruo 37.0 | ± 0.20mm |

| 1.500 ruo 2,000" | ±.010" | 37.0 ruo 50.0 | ± 0.25mm |

| 2.000 ruo 2.500” | ±.012" | 50.0 ruo 62.0 | ± 0.30mm |

| 2.500 ruo 3.500" | ±.014" | 62.0 ruo 87.0 | ± 0.35mm |

| 3.500 ruo 5,000" | ±.017" | 87.0 ruo 125.0 | ± 0.40mm |

| 5.000 ruo 7.500” | ±.020" | 125.0 ruo 190.0 | ± 0.50mm |

| 7.500 ruo 10,000" | ±.022" | 190.0 ruo 250.0 | ± 0.57mm |

| 10.000 ruo 12.500" | ±.025" | 250.0 ruo 312.0 | ± 0.60mm |

| 12.500 ruo 15.000 | ±.028" | 312.0 ruo 375.0 | ± 0.70mm |