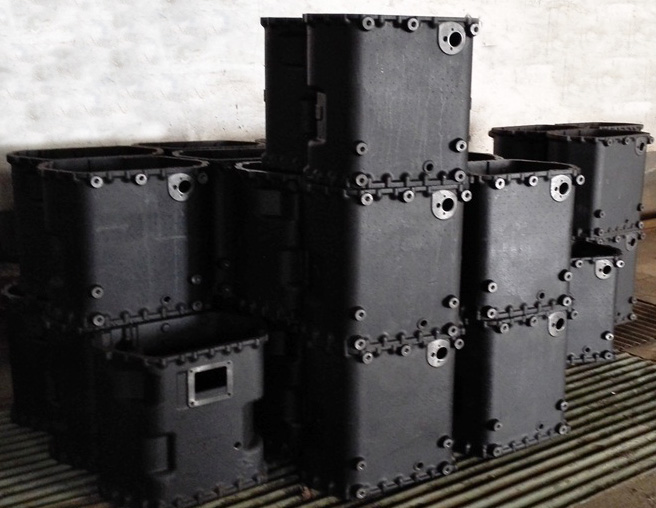

Ụlọ ọrụ nkedo igwe anaghị agba nchara sitere na China nwere OEM Custom na CNC Machining Services.

Ígwè nkedo bụ ihe nkedo ígwè-carbon nwere ihe ndị ọzọ a na-eme site na ịgbaze ígwè ezi, ihe mkpofu na ihe ndị ọzọ. Maka ihe dị iche na nchara na nchara nkedo, a kọwapụtara ígwè nkedo dị ka ihe nkedo nwere ọdịnaya carbon (min 2.03%) nke na-eme ka a mata ngbanwe nke oge ikpeazụ yana mgbanwe eutectic.

Dabere na nkowa kemịkalụ, igwe nkedo nwere ike ịbụ nke anaghị agba nchara ma ọ bụ alloy. Ogo nke ígwè alloyed dị nnọọ obosara karị, ha nwere ma ọ bụ ihe ndị a na-ahụkarị, dị ka silicon na manganese, ma ọ bụ ihe mgbakwunye pụrụ iche, dị ka nickel, chromium, aluminum, molybdenum, tungsten, ọla kọpa, vana-dium, titanium, gbakwunyere. ndị ọzọ. N'ikwu okwu n'ozuzu, a pụrụ ikewa ígwè nkedo ahụ ka ọ bụrụ ígwè isi awọ, ígwè ducitle (iron nodular), ígwè nkedo na-acha ọcha, ígwè graphite gbakọrọ ọnụ na ígwè nkedo a na-apụghị ịgbagha agbagha.

Ngwa akụrụngwa dị makaNkedo Vacuum

• Ígwè isi awọ: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10-GG40.

• Iron Ductile ma ọ bụ Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Carbon Steel: Carbon dị ala, obere carbon na nnukwu carbon ígwè sitere na AISI 1020 ruo AISI 1060.

• Ihe nkedo ígwè: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo... wdg na arịrịọ.

• Igwe anaghị agba nchara: AISI 304, AISI 304L, AISI 316, AISI 316L na ọkwa igwe anaghị agba nchara ndị ọzọ.

• Bras & ọla kọpa.

• Ngwa ndị ọzọ na ụkpụrụ na-arịọ

Isi usoro mmepụta nke Vacuum Casting

Ụdị & Nhazi Ngwá Ọrụ → Ime ụkpụrụ → Usoro ịkpụzi → Nyocha ihe mejupụtara kemịkalụ → Na-agbaze & Ịwụ → Nhicha, Egweri & Mgbawa Mgbawa → Nhazi ma ọ bụ nkwakọ ngwaahịa maka Mbupu

Ike nyocha nkedo ájá

• Spectrographic na ntuziaka quantitative analysis

• Metallographic analysis

• Brinell, Rockwell na Vickers nyocha ike siri ike

• Mechanical onwunwe nyocha

• Nnwale mmetụta okpomọkụ dị ala na nke nkịtị

• Nnyocha ịdị ọcha

• Nyocha UT, MT na RT

Usoro nkedo mgbe emechara

• Deburring & Nhicha

• Mgbawa agbawa / ájá peening

• Ọgwụgwọ okpomọkụ: Normalization, Quench, Tempering, Carburization, Nitriding

• Ngwọta dị n'elu: Passivation, Andonizing, Electroplating, Hot Zinc Plating, Zinc Plating, Nickel Plating, Polishing, Electro-Polishing, Painting, GeoMet, Zintec

• Nrụ ọrụ: Ntụgharị, igwe-egwe ọka, ịsụ mmiri, ịkwọ ụgbọ mmiri, ịsọpụrụ, egweri,

Usoro azụmahịa izugbe

• Isi ọrụ na-aga n'ihu: Ajụjụ & Nkwupụta → Nkwenye nkọwa / atụmatụ mbelata ọnụ ahịa → Mmepe Ngwá Ọrụ → Nkedo Ọnwụnwa → Nkwenye nlele → Usoro ikpe → Mmepụta Mass → Na-aga n'ihu n'usoro iwu.

• Oge ndu: Atụmatụ 15-25 ụbọchị maka mmepe ngwá ọrụ na atụmatụ 20 ụbọchị maka mmepụta oke.

• Usoro ịkwụ ụgwọ: A ga-enwe mkparịta ụka.

• Ụzọ ịkwụ ụgwọ: T/T, L/C, West Union, Paypal.